Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Thyristor Modules

Thyristor modules are key components in power electronics technology. They consist of one or more thyristors encapsulated in a compact housing. Thyristors are four-layer, three-terminal semiconductor devices that are primarily used in applications that control and regulate high-power AC or DC current. They can quickly switch from a high-impedance state to a low-impedance conduction state based on a trigger signal, thereby achieving precise control of current.

Features and Benefits of Thyristor Modules

High power handling capability: Thyristor modules can withstand extremely high voltages and currents, making them suitable for industrial-grade power conversion and control systems.

Fast response time: Very short switching times and low losses ensure high-efficiency operation.

Reliability and durability: Rugged design, stable operation in harsh environments, and long life.

Easy integration: Modular design simplifies installation and reduces maintenance requirements.

Overload protection: Built-in protection mechanisms such as over-temperature and over-current protection enhance system safety.

Versatile applications: Widely used in a variety of applications requiring precise current control.

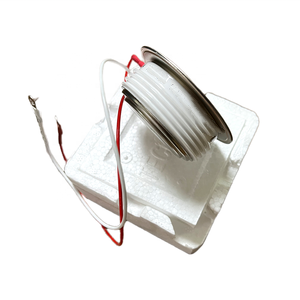

(Thyristor module for thyristor welding machine AC DC power module Diode module)

Specification of Thyristor module for thyristor welding machine AC DC power module Diode module

Thyristors are an essential component in AC DC power modules and diode modules, ensuring safe and efficient operation of the equipment. These devices have become increasingly important in industrial settings as they provide stable and reliable power supplies that meet various industry standards.

In AC DC power modules, thyristors are used to regulate the current output and protect against overcurrent or short circuits. They are typically made from a variety of materials such as silicon carbide, titanium, and aluminum, with different specifications based on their performance requirements.

One of the key features of thyristors is their ability to switch quickly and efficiently, making them ideal for use in high-speed applications where speed is critical. They also have a low internal resistance, which allows them to operate at higher voltages without overheating or damage.

In diode modules, thyristors are used to control the flow of electricity between two electrodes. They are often used in reverse voltage (VCE) circuits, where the voltage across the diode acts as a protective mechanism against overvoltage or short circuiting.

The specific specification of a thyristor module will depend on its intended application and usage conditions. It may include factors such as the thyristor’s rating, thermal stability, and electrical characteristics like its forward voltage gain, reverse saturation voltage, and ideality factor.

It is important to choose a thyristor module that meets the specific needs of your application and complies with relevant safety and performance standards. This may involve choosing the appropriate thyristor material, specifying the appropriate rated voltage and current, and testing the module to ensure it functions properly under varying operating conditions.

(Thyristor module for thyristor welding machine AC DC power module Diode module)

Applications of Thyristor module for thyristor welding machine AC DC power module Diode module

Thyristors are electronic components that control the flow of current in an electrical circuit. They are widely used in various applications, including thyristor welding machines and AC DC power modules.

In thyristor welding machines, thyristors are used to switch the flow of electricity to either positive or negative depending on whether a wire is being or not. The thyristor’s voltage rating determines its ability to withstand high temperatures, which makes it suitable for use in harsh industrial environments where precise temperature control is critical. Additionally, thyristors can be used as a starting point for electrical circuits, making them versatile for a wide range of applications.

On the other hand, AC DC power modules are electrical devices that convert alternating current (AC) into direct current (DC). They are commonly used in various applications such as electronic equipment, data centers, and industrial automation systems. The quality and efficiency of an AC DC power module depend on several factors, including the type of power supply, the components used, and the application requirements.

One of the most significant advantages of using thyristor modules in AC DC power modules is their ability to efficiently store and regulate energy. Unlike traditional power supplies that require additional components, thyristor-based power modules have built-in energy storage capabilities that allow them to maintain a consistent output even when there is a lack of input power. This feature makes them ideal for use in power grids that operate continuously, such as in renewable energy sources.

Another advantage of thyristor-based power modules is their ability to increase system efficiency. By regulating the flow of electricity, thyristors can reduce energy waste and improve overall system performance. For example, thyristors can be used to boost the power output of a motor during periods of low demand, reducing the need for additional power generation sources.

In conclusion, thyristors are essential components of both thyristor welding machines and AC DC power modules. Their versatility and efficiency make them indispensable in many industries, and the introduction of thyristor-based power modules has significantly improved the performance of these devices. As technology continues to advance, we can expect to see even more innovative applications of thyristors in the future.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Thyristor module for thyristor welding machine AC DC power module Diode module, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Thyristor module for thyristor welding machine AC DC power module Diode module

1. What is a thyristor module?

A thyristor module is a circuit component that converts alternating current (AC) into direct current (DC). It consists of two thyristors connected in a voltage-controlled manner, which allows the module to regulate the flow of electricity.

2. How do thyristor modules work?

Thyristor modules use electronic components such as diodes and transistors to control the flow of electricity. When one thyristor is turned on or off, it controls the flow of electricity through the other thyristor. This ensures that the AC input is converted into DC output without loss of energy.

3. What types of thyristor modules are available?

There are several types of thyristor modules available for thyristor welding machines, including analog modules, digital modules, and hybrid modules. Analog modules use basic diode characteristics to control the flow of electricity, while digital modules use more advanced electronics to control the thyristors. Hybrid modules combine both analog and digital technologies to provide even greater control over the thyristor flow.

4. What is the difference between a thyristor module and a diode module?

The main difference between a thyristor module and a diode module is their role in converting AC into DC. A thyristor module is responsible for controlling the flow of electricity, while a diode module is responsible for protecting the electronic components from damage caused by surges in voltage.

5. How much does a thyristor module cost?

The cost of a thyristor module depends on several factors, including the type of thyristor module used, the quality of the electronic components used, and any additional features required for the particular application. However, in general, thyristor modules can be relatively inexpensive compared to other electronic components used in thyristor machines.

(Thyristor module for thyristor welding machine AC DC power module Diode module)

REQUEST A QUOTE

RELATED PRODUCTS

SKKH27316E Semikron Thyristor/Diode Module

TECHSEM Thyristor Module MTC250-16-413F3D MTC250A1600V-413F3D Diode Module IGBT MTC250-18-413F3D MTC250-16 Module

thyristor Hot offer diode module TMTC 570-14 on auxiliary inverters, motor drives and servo drives and and PFC

STOCK electronics component IGBT MODULE Diode Thyristor SCR transistors mosfet IC chips 70HF120

Good quality hot supply Thyristor SCR Module SG3000GXH24 module