Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

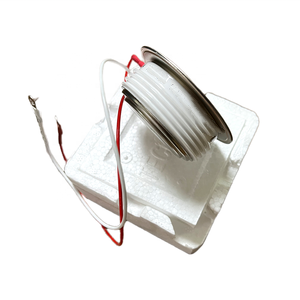

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(Cooling Heat Sink Heatsink CNC Machining Light Cnc Machining Deep Processing Plate Led Aluminum Customized Micro Machining)

Specifications of Cooling Heat Sink Heatsink CNC Machining Light Cnc Machining Deep Processing Plate Led Aluminum Customized Micro Machining

The Cooling Heat Sink, crafted through precision CNC machining, is a high-performance solution designed to efficiently manage heat dissipation in various applications. This heatsink is ideal for use in LED lighting systems, electronic devices, and other equipment requiring effective thermal management. Manufactured using advanced CNC machining techniques, it ensures exceptional accuracy, durability, and consistency in every piece.

The heatsink is made from high-quality aluminum, a material renowned for its excellent thermal conductivity, lightweight properties, and corrosion resistance. Its design can be customized to meet specific requirements, making it suitable for micro-machining and deep processing applications. Whether you need intricate patterns, unique shapes, or precise dimensions, the CNC machining process allows for unparalleled customization to fit your exact needs.

The surface of the heatsink can undergo additional deep processing, such as anodizing or polishing, to enhance its aesthetic appeal and improve its resistance to wear and tear. This makes it not only functional but also visually appealing for applications where appearance matters. The lightweight nature of aluminum ensures that the heatsink does not add unnecessary bulk to your devices, while its robust construction guarantees long-lasting performance.

This cooling heatsink is particularly well-suited for LED applications, where efficient heat dissipation is critical to maintaining optimal performance and extending the lifespan of the lighting system. Its micro-machining capabilities allow for the creation of intricate fin designs, maximizing surface area for improved heat transfer. Additionally, the CNC machining process ensures tight tolerances and smooth finishes, reducing the risk of thermal resistance and enhancing overall efficiency.

In summary, this Cooling Heat Sink combines precision CNC machining, high-quality aluminum, and customizable design options to deliver a reliable and efficient thermal management solution. Whether for industrial, commercial, or consumer applications, this heatsink offers superior performance, durability, and versatility, making it an excellent choice for your cooling needs.

(Cooling Heat Sink Heatsink CNC Machining Light Cnc Machining Deep Processing Plate Led Aluminum Customized Micro Machining)

Applications of Cooling Heat Sink Heatsink CNC Machining Light Cnc Machining Deep Processing Plate Led Aluminum Customized Micro Machining

Cooling heat sinks are essential components in various industries, particularly in electronics, where they play a critical role in managing heat dissipation to ensure optimal performance and longevity of devices. CNC machining has revolutionized the production of these heat sinks, offering precision, customization, and efficiency. With advanced CNC machining techniques, manufacturers can create highly specialized heat sinks tailored to specific applications, such as LED lighting, microelectronics, and high-performance computing.

One of the key applications of CNC-machined heat sinks is in LED lighting systems. LEDs generate significant heat during operation, and without proper thermal management, their lifespan and efficiency can be drastically reduced. Customized aluminum heat sinks, crafted through CNC machining, provide excellent thermal conductivity and can be designed to fit the exact dimensions and requirements of LED modules. This ensures effective heat dissipation, enhancing the performance and durability of LED lighting solutions.

In the realm of microelectronics, where components are becoming increasingly compact, CNC machining enables the production of micro heat sinks with intricate designs. These heat sinks are crucial for maintaining the thermal stability of sensitive electronic components, preventing overheating and potential damage. The precision of CNC machining allows for the creation of complex geometries, such as deep processing plates and fine fins, which maximize surface area for heat transfer.

CNC machining also supports the production of heat sinks for high-performance computing systems, where thermal management is critical to maintaining processing speeds and preventing system failures. Customized aluminum heat sinks, designed through CNC processes, can be optimized for specific airflow and cooling requirements, ensuring efficient heat dissipation even under heavy workloads.

In summary, CNC machining has become indispensable in the manufacturing of cooling heat sinks, offering unparalleled precision, customization, and versatility. From LED lighting to microelectronics and high-performance computing, CNC-machined heat sinks provide reliable thermal management solutions, ensuring the efficiency and longevity of modern electronic devices. Whether it’s deep processing plates, micro machining, or custom designs, CNC technology continues to push the boundaries of what’s possible in heat sink production.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Cooling Heat Sink Heatsink CNC Machining Light Cnc Machining Deep Processing Plate Led Aluminum Customized Micro Machining, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Cooling Heat Sink Heatsink CNC Machining Light Cnc Machining Deep Processing Plate Led Aluminum Customized Micro Machining

When it comes to cooling heat sinks and CNC machining, especially for applications like LED lighting, micro machining, and deep processing, there are several common questions that arise. Here are five frequently asked questions (FAQs) about these processes:

1. **What materials are best for cooling heat sinks in CNC machining?**

Aluminum is the most commonly used material for cooling heat sinks due to its excellent thermal conductivity, lightweight nature, and cost-effectiveness. For more demanding applications, copper is also used because of its superior thermal performance, though it is heavier and more expensive. Both materials are ideal for CNC machining, allowing for precise customization and intricate designs.

2. **How does CNC machining improve the performance of heat sinks?**

CNC machining enables the creation of highly precise and complex geometries, such as fins, channels, and grooves, which maximize surface area and improve heat dissipation. This level of precision ensures optimal thermal performance, making CNC-machined heat sinks ideal for high-performance applications like LED lighting and microelectronics.

3. **Can CNC machining handle micro-machining for small heat sinks?**

Yes, CNC machining is capable of micro-machining, which is essential for creating small, intricate heat sinks used in compact devices like LEDs and microelectronics. Advanced CNC machines can achieve tolerances as low as a few micrometers, ensuring high accuracy and consistency even for tiny components.

4. **What are the benefits of customizing heat sinks for specific applications?**

Customized heat sinks are designed to meet the exact thermal and dimensional requirements of a specific application. This ensures better heat management, improved efficiency, and longer lifespan for the components. Customization also allows for integration with other parts, reducing assembly time and costs.

5. **How does deep processing enhance heat sink performance?**

Deep processing techniques, such as deep drilling or milling, allow for the creation of internal channels or cavities within the heat sink. These features improve airflow and heat transfer, making the heat sink more effective at cooling high-power components. Deep processing is particularly useful for advanced applications where traditional designs may not suffice.

In summary, CNC machining and deep processing play a critical role in creating high-performance, customized heat sinks for applications like LED lighting and microelectronics. By leveraging advanced techniques and materials, manufacturers can achieve superior thermal management and meet the specific needs of their projects.

(Cooling Heat Sink Heatsink CNC Machining Light Cnc Machining Deep Processing Plate Led Aluminum Customized Micro Machining)

REQUEST A QUOTE

RELATED PRODUCTS

RDS Electronics-Customized size super cooling radiator 100*60*10MM aluminum heatsink

custom 1000w bonded fin cooler 2u server Vc vapor chamber cpu gpu heatsink heat sink for Artificial Intelligence Servers

High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink

best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink

100x100mm Aluminum vc vapor chamber radiator heatsink custom heat pipe heat sink for led quantum board