Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

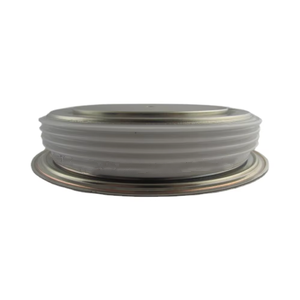

Overview of High-Voltage Assemblies and HV Series

High-voltage assemblies and components within the HV series are engineered for applications requiring the handling of high electrical potentials. These devices are critical in power transmission, medical imaging, industrial processing, and scientific research equipment. They are designed to operate reliably under extreme voltage conditions, ensuring safety and efficiency in systems that demand precise control over high voltages. High-voltage assemblies often integrate multiple components such as resistors, capacitors, transformers, and insulators into a single unit, optimized for performance in challenging environments.

Features of High-Voltage Assemblies and HV Series

- High Voltage Tolerance: Capable of withstanding and managing extremely high voltages, essential for applications like X-ray machines and particle accelerators.

- Compact Design: Integrates various components into a single assembly, reducing size and weight while maintaining functionality.

- Enhanced Safety Measures: Incorporates robust insulation and protective features to prevent electrical hazards.

- Thermal Management: Equipped with advanced cooling solutions to manage heat effectively during operation.

- Reliability and Durability: Built to endure harsh conditions, including temperature extremes and mechanical stress.

- Customizable Solutions: Offers flexibility in design to meet specific application requirements.

- Precision Control: Ensures accurate voltage regulation and stability, crucial for sensitive applications.

- Wide Operating Range: Operates efficiently across a broad spectrum of voltages and currents.

- Compliance with Standards: Adheres to international standards and regulations for high-voltage equipment.

(High Voltage IATF 16949:2016 Cables & Cable Assemblies Auto Custom Motor Assembly Custom Automotive Wire Harness)

Specification of High Voltage IATF 16949:2016 Cables & Cable Assemblies Auto Custom Motor Assembly Custom Automotive Wire Harness

High Voltage IATF 16949:2016 Cables & Cable Assemblies are engineered to meet the rigorous demands of the automotive industry, ensuring superior performance, reliability, and safety. These cables and assemblies are specifically designed for high-voltage applications, making them ideal for electric vehicles (EVs), hybrid vehicles, and other automotive systems requiring robust electrical connectivity. Compliant with the IATF 16949:2016 standard, these products adhere to the highest quality management system requirements, ensuring consistent performance and durability in the most demanding environments.

The custom motor assembly and automotive wire harness solutions are tailored to meet the unique specifications of each application. These assemblies are crafted with precision, incorporating high-quality materials and advanced manufacturing techniques to ensure optimal electrical conductivity, thermal resistance, and mechanical strength. The wire harnesses are designed to withstand extreme temperatures, vibrations, and exposure to chemicals, ensuring long-term reliability and performance.

Key features of these high-voltage cables and assemblies include excellent insulation properties, resistance to abrasion, and superior shielding to minimize electromagnetic interference (EMI). The use of high-grade materials such as cross-linked polyethylene (XLPE) or silicone rubber ensures thermal stability and resistance to environmental stressors. Additionally, the connectors and terminals are designed for secure and efficient connections, reducing the risk of failure and enhancing overall system performance.

Customization is a cornerstone of these products, allowing for tailored solutions that meet specific automotive requirements. Whether it’s a unique wire harness configuration, specialized cable lengths, or specific connector types, these assemblies are designed to integrate seamlessly into complex automotive systems. The result is a product that not only meets but exceeds industry standards, providing automotive manufacturers with reliable, high-performance solutions for their high-voltage applications.

In summary, High Voltage IATF 16949:2016 Cables & Cable Assemblies, along with custom motor assemblies and automotive wire harnesses, represent the pinnacle of automotive electrical engineering. They deliver unmatched quality, durability, and performance, making them the ideal choice for modern automotive systems.

(High Voltage IATF 16949:2016 Cables & Cable Assemblies Auto Custom Motor Assembly Custom Automotive Wire Harness)

Applications of High Voltage IATF 16949:2016 Cables & Cable Assemblies Auto Custom Motor Assembly Custom Automotive Wire Harness

High Voltage IATF 16949:2016 Cables & Cable Assemblies, along with Custom Motor Assemblies and Automotive Wire Harnesses, are critical components in the automotive industry, designed to meet the stringent quality and safety standards required for modern vehicles. These products are engineered to deliver superior performance, reliability, and durability in high-voltage applications, making them ideal for electric vehicles (EVs), hybrid vehicles, and other advanced automotive systems.

The IATF 16949:2016 certification ensures that these cables and assemblies are manufactured under the highest quality management standards, guaranteeing consistency, traceability, and compliance with automotive industry requirements. High-voltage cables are specifically designed to handle the increased power demands of electric and hybrid vehicles, ensuring efficient energy transmission while minimizing power loss. These cables are constructed with high-quality insulation materials that provide excellent thermal stability, resistance to abrasion, and protection against environmental factors such as moisture, chemicals, and extreme temperatures.

Custom Motor Assemblies play a vital role in automotive applications, offering tailored solutions for electric motors used in EVs and hybrid systems. These assemblies are precision-engineered to meet specific performance requirements, ensuring optimal efficiency, reduced energy consumption, and enhanced vehicle performance. The integration of high-voltage cables and custom motor assemblies ensures seamless power delivery and reliable operation in demanding automotive environments.

Automotive Wire Harnesses are another essential component, providing organized and secure connections for electrical systems within vehicles. Custom wire harnesses are designed to meet the unique needs of each vehicle model, ensuring proper routing, protection, and connectivity for all electrical components. These harnesses are built to withstand the rigors of automotive use, including vibration, heat, and exposure to harsh conditions.

Together, these products form the backbone of modern automotive electrical systems, enabling the development of safer, more efficient, and environmentally friendly vehicles. By adhering to IATF 16949:2016 standards, manufacturers can ensure that their high-voltage cables, custom motor assemblies, and wire harnesses meet the highest levels of quality and reliability, supporting the automotive industry’s transition toward electrification and innovation.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High Voltage IATF 16949:2016 Cables & Cable Assemblies Auto Custom Motor Assembly Custom Automotive Wire Harness, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High Voltage IATF 16949:2016 Cables & Cable Assemblies Auto Custom Motor Assembly Custom Automotive Wire Harness

High Voltage IATF 16949:2016 Cables & Cable Assemblies, Auto Custom Motor Assemblies, and Custom Automotive Wire Harnesses are critical components in modern automotive systems, ensuring reliable performance and safety. Here are five frequently asked questions about these products:

1. **What is IATF 16949:2016 certification, and why is it important for automotive cables and assemblies?**

IATF 16949:2016 is an international quality management standard specifically designed for the automotive industry. Products with this certification, such as high-voltage cables and wire harnesses, meet stringent quality and safety requirements. This ensures they are reliable, durable, and capable of withstanding the demanding conditions of automotive applications, including extreme temperatures, vibrations, and electrical loads.

2. **What are the key features of high-voltage cables used in automotive applications?**

High-voltage cables are designed to handle significant electrical loads while maintaining safety and efficiency. They are typically insulated with materials like cross-linked polyethylene (XLPE) or silicone to resist heat, abrasion, and chemicals. These cables are also engineered to minimize electromagnetic interference (EMI) and ensure optimal performance in electric and hybrid vehicles.

3. **How are custom automotive wire harnesses tailored to specific vehicle requirements?**

Custom wire harnesses are designed to meet the unique electrical and mechanical needs of a vehicle. Engineers work closely with manufacturers to create harnesses that fit precise layouts, accommodate specific connectors, and ensure proper routing. This customization enhances performance, reduces installation time, and minimizes the risk of errors.

4. **What role do auto custom motor assemblies play in electric vehicles (EVs)?**

Auto custom motor assemblies are integral to the operation of electric vehicles, providing the necessary power and control for motors. These assemblies are designed to integrate seamlessly with other vehicle components, ensuring efficient energy transfer and reliable performance. Customization allows for compatibility with specific motor types and vehicle designs.

5. **How do these products contribute to the safety and efficiency of modern vehicles?**

High-voltage cables, wire harnesses, and motor assemblies are engineered to meet rigorous safety standards, reducing the risk of electrical failures, short circuits, or fires. Their efficient design minimizes energy loss, contributing to better fuel economy in traditional vehicles and extended range in electric vehicles. By adhering to IATF 16949:2016 standards, these products ensure consistent quality and reliability, supporting the overall performance of automotive systems.

These FAQs highlight the importance of high-quality, certified components in the automotive industry, emphasizing their role in safety, efficiency, and performance.

(High Voltage IATF 16949:2016 Cables & Cable Assemblies Auto Custom Motor Assembly Custom Automotive Wire Harness)

REQUEST A QUOTE

RELATED PRODUCTS

Custom High Voltage/Low Voltage Machinery Wires Cables & Cable Assemblies OEM ODM with Custom Size Color Coating

2POS high voltage connector Electric,Hybrid & Fuel Cell Cable Assemblies

XGN15-12 Medium Voltage High Voltage Electric Switchgear Electric Assemblies Panel 11KV Ring Main Unit

15kv 25kv termination high voltage cable jointing kit Silicone Rubber electrical cold Shrink cable assemblies

Custom EV Wiring Harness High Voltage Cable Assemblies UL OEM/ODM Factory Production ‘s for Consumers