Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

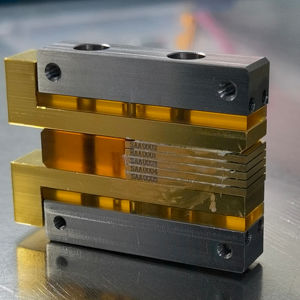

(High Power Custom Aluminium Power Amplifier Rectangular Led Bar heatsink Profile Extrusion Radiators Aluminum Heat Sink)

Specifications of High Power Custom Aluminium Power Amplifier Rectangular Led Bar heatsink Profile Extrusion Radiators Aluminum Heat Sink

The High Power Customized Light Weight Aluminum Power Amplifier Rectangular LED Bar Heatsink Account Extrusion Radiator is engineered to supply remarkable thermal management for high-performance electronic and illumination systems. Constructed from premium-grade light weight aluminum alloy (commonly 6063-T5 or 6061), this heatsink combines lightweight durability with phenomenal warmth dissipation, making it optimal for power amplifiers, LED bars, and other high-power tools. Its rectangular account is maximized for surface maximization, making sure effective warm transfer via convection, conduction, and radiation. The extrusion procedure enables accurate, complicated geometries, consisting of thick fin ranges, grooves, and mounting channels, tailored to improve air flow and thermal performance. Requirement lengths range from 100mm to 3000mm, with adjustable sizes (20mm– 250mm) and heights (10mm– 150mm) to fit certain applications. The material’s high thermal conductivity (180– 220 W/m · K) makes sure fast heat absorption and circulation, while its corrosion-resistant surface is usually anodized (all-natural, black, or personalized colors) for included protection and visual convenience. Weight is reduced (aluminum thickness: ~ 2.7 g/cm ³) without compromising structural honesty, ideal for both stationary and mobile arrangements. Modification alternatives include pre-drilled holes, threaded inserts, and bespoke installing setups to incorporate effortlessly with amplifiers, LED drivers, or PCB formats. The heatsink operates dependably in temperatures from -50 ° C to 250 ° C, making certain security under extreme conditions. Its layout minimizes hotspots, lengthening element life-span and preserving performance in telecommunications, auto, industrial automation, and stage lights systems. RoHS and get to compliance assurances environmental safety and security, while the extruded one-piece structure removes joints for constant thermal efficiency. Suitable with thermal user interface materials like pastes or pads, it makes certain optimal call with heat-generating parts. This heatsink is a cost-efficient, scalable solution for high-power thermal obstacles, stabilizing effectiveness, customization, and sturdiness.

(High Power Custom Aluminium Power Amplifier Rectangular Led Bar heatsink Profile Extrusion Radiators Aluminum Heat Sink)

Applications of High Power Custom Aluminium Power Amplifier Rectangular Led Bar heatsink Profile Extrusion Radiators Aluminum Heat Sink

High power customized aluminum power amplifier rectangle-shaped LED bar heatsink profile extrusion radiators are engineered to deliver superior thermal monitoring sought after applications. Crafted from top-quality aluminum, these heatsinks utilize extrusion technology to develop complicated, lightweight accounts with ideal surface area for rapid warmth dissipation. Their personalized style makes certain seamless combination into diverse systems, making them perfect for industries where efficient cooling is vital to performance and durability.

In telecoms and audio systems, these heatsinks are crucial for cooling power amplifiers in RF transmitters, base terminals, and high-fidelity audio tools. Their ability to take care of high thermal lots stops getting too hot, guaranteeing steady signal transmission and audio top quality. The rectangular profile allows small installment in limited areas, while custom dimensions deal with particular amplifier designs.

High-power LED illumination systems, such as industrial fixtures, stage lights, and building installments, depend on these heatsinks to preserve ideal LED efficiency. By effectively drawing heat far from LED ranges, they prevent lumen depreciation and expand life expectancy, also in continuous operation. The extruded design suits linear LED bars, supplying consistent air conditioning across lengthy periods.

Power electronic devices, consisting of inverters, motor drives, and converters, gain from the heatsink’s durable thermal conductivity. It stabilizes temperature-sensitive components like IGBTs and MOSFETs, boosting efficiency in renewable energy systems such as solar inverters and wind turbines. Electric car charging stations and onboard electronic devices likewise utilize these radiators to manage warm in high-current atmospheres.

Industrial automation devices, such as CNC equipments and robotic systems, utilizes customized light weight aluminum heatsinks to cool down servo drives and power materials, reducing downtime. In medical imaging and analysis tools, precise thermal control guarantees precision and integrity.

The extruded aluminum construction supplies deterioration resistance and resilience, suitable for severe settings. Personalized fins, base density, and mounting options allow tailored services for unique thermal difficulties. By incorporating high thermal conductivity with versatile design, these heatsinks are a functional, cost-effective service for keeping peak efficiency in high-power applications throughout industries.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High Power Custom Aluminium Power Amplifier Rectangular Led Bar heatsink Profile Extrusion Radiators Aluminum Heat Sink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High Power Custom Aluminium Power Amplifier Rectangular Led Bar heatsink Profile Extrusion Radiators Aluminum Heat Sink

What are the key benefits of using aluminum for high-power heatsinks? Aluminum is ideal for heatsinks due to its excellent thermal conductivity (205–235 W/m·K), which efficiently transfers heat away from sensitive components. Its lightweight nature reduces overall system weight, and its corrosion resistance ensures longevity. Aluminum’s malleability allows for complex extrusion profiles, enabling optimized surface area for heat dissipation while remaining cost-effective for custom designs.

How customizable are these aluminum heatsinks? These heatsinks are highly customizable. Manufacturers can adjust dimensions, fin density, base thickness, and surface treatments (e.g., anodizing, powder coating) to meet specific thermal and aesthetic requirements. Custom extrusion dies can be created for unique profiles, and post-processing like CNC machining ensures compatibility with components like power amplifiers or LED bars.

What factors determine the thermal performance of these heatsinks? Thermal efficiency depends on design parameters like surface area, fin geometry, airflow, and contact with the heat source. Larger surface areas and tightly spaced fins improve passive cooling, while thicker bases enhance heat conduction. Active cooling (e.g., fans) can further boost performance. Computational modeling and real-world testing ensure designs meet thermal demands of high-power applications.

Are these heatsinks suitable for harsh environments? Yes. Aluminum’s natural corrosion resistance, combined with anodizing or coatings, protects against moisture, chemicals, and oxidation. They operate reliably in temperatures ranging from -50°C to 200°C, making them suitable for industrial, outdoor, or high-temperature environments. Rugged designs minimize dust/particle buildup, ensuring consistent performance.

Can these heatsinks be used for applications beyond power amplifiers and LED bars? Absolutely. While optimized for amplifiers and LED lighting, the extruded profiles work for any high-power electronics, including motor drives, inverters, and RF systems. Customizable mounting options (e.g., screw holes, brackets) and thermal interface materials (TIMs) ensure compatibility with diverse devices requiring efficient thermal management.

(High Power Custom Aluminium Power Amplifier Rectangular Led Bar heatsink Profile Extrusion Radiators Aluminum Heat Sink)

REQUEST A QUOTE

RELATED PRODUCTS

Hot Heatsink Cooler Anodized Extruded Large Aluminum Extrusion Profile Heat Sink

Industrial Aluminum Profile Anodized Heatsink 6061 6063 CNC Hollow Extruded Heat Sink

Black Anodized Aluminum Heatsinks Good Performance Aluminum Profiles Extruded Aluminum Heatsink

Customized Precision Water Cooling Amplifier Heatsink Aluminium Heatsink

Cooling Heat Sink Heatsink CNC Machining Light Cnc Machining Deep Processing Plate Led Aluminum Customized Micro Machining