Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

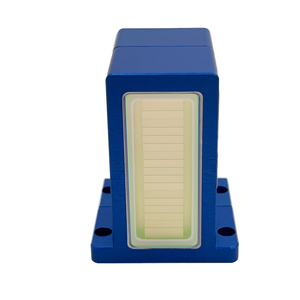

(Black Anodized Aluminum Heatsinks Good Performance Aluminum Profiles Extruded Aluminum Heatsink)

Specifications of Black Anodized Aluminum Heatsinks Good Performance Aluminum Profiles Extruded Aluminum Heatsink

Black anodized aluminum heatsinks offer effective thermal management for digital devices. The heatsinks make use of high-grade light weight aluminum. The product provides outstanding warmth conductivity. This assists transfer warm away from sensitive components quickly. The anodized layer adds sturdiness. It stands up to corrosion and scrapes. The surface coating improves long-term performance.

These heatsinks are made via extrusion. The process creates exact forms and layouts. It permits custom accounts to fit details applications. The extruded aluminum profiles have big surface areas. This increases warmth dissipation. Fins or ridges are often added. These features enhance airflow and cooling down efficiency.

The black anodized coating offers numerous objectives. It safeguards against ecological damages. It protects against oxidation caused by wetness or chemicals. The dark color improves warmth radiation. It also gives a clean, expert look. The coating is electrically non-conductive. This decreases the danger of short circuits.

These heatsinks operate in numerous industries. They cool electronic devices like CPUs, LEDs, and power products. They manage high temperatures in automobile systems. They sustain industrial machinery and renewable energy devices. Customized shapes and sizes are offered. This makes certain compatibility with different tools.

The aluminum utilized is light-weight but solid. It holds up against physical anxiety without bending. The product is recyclable. This makes it eco-friendly. Anodizing prolongs the item’s life expectancy. It minimizes the requirement for frequent replacements.

Setup is easy. The heatsinks feature pre-drilled openings or glue choices. They affix securely to warmth sources. Thermal interface materials like paste or pads boost get in touch with. This takes full advantage of warmth transfer.

Performance screening makes certain reliability. The heatsinks satisfy sector requirements for thermal resistance. They run properly in temperatures from -40 ° C to 150 ° C. The design reduces dust buildup. This keeps consistent cooling in time.

Black anodized light weight aluminum heatsinks equilibrium price and quality. They provide inexpensive thermal solutions without jeopardizing performance. Their adaptability fits both little and large applications. Reduced maintenance needs make them practical for lasting use.

(Black Anodized Aluminum Heatsinks Good Performance Aluminum Profiles Extruded Aluminum Heatsink)

Applications of Black Anodized Aluminum Heatsinks Good Performance Aluminum Profiles Extruded Aluminum Heatsink

Black anodized aluminum heatsinks are extensively utilized in electronics and industrial tools. These heatsinks handle heat successfully. They protect against devices from overheating. The anodized finish improves rust resistance. It also reinforces the surface area. This makes the heatsinks last much longer. The black color helps radiate warmth much faster. This improves cooling performance.

Extruded light weight aluminum profiles make these heatsinks efficient. The extrusion procedure develops precise forms. It permits intricate designs. This guarantees the heatsink fits specific applications. Extruded light weight aluminum has high thermal conductivity. Warm moves rapidly from the source to the fins. The big surface of the fins dissipates warmth right into the air.

These heatsinks work in numerous markets. Computers utilize them for CPUs and GPUs. LED lights systems count on them to cool down high-power LEDs. Automotive electronics require heatsinks for battery administration and motor controllers. Renewable resource systems use them in solar inverters and power converters. Industrial equipment relies on them to protect sensitive elements.

The black anodized coating adds benefits. It withstands scrapes and chemicals. This is necessary in extreme atmospheres. The coating does not peel off or discolor. It keeps appearance over time. The dark shade decreases glare. This serves in customer electronic devices and exterior installments.

Aluminum is lightweight. This makes the heatsinks simple to set up. They do not include unnecessary weight to tools. Light weight aluminum is also recyclable. This sustains green production.

Customization is simple with extruded light weight aluminum. Makers adjust measurements, fin thickness, and form. This makes certain optimal performance for each application. Pre-drilled holes and placing options simplify setting up.

These heatsinks call for minimal maintenance. They do not need coatings or therapies after installation. The long lasting layout takes care of heats. It does regularly in demanding problems.

Black anodized aluminum heatsinks balance expense and efficiency. They are less costly than copper options. They provide comparable thermal effectiveness. This makes them a functional choice for automation.

The mix of anodization and extrusion develops trusted thermal services. Devices stay cooler. Efficiency boosts. Lifespan expands. These heatsinks meet the demands of modern-day technology. They adapt to advancing industry demands.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Black Anodized Aluminum Heatsinks Good Performance Aluminum Profiles Extruded Aluminum Heatsink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Black Anodized Aluminum Heatsinks Good Performance Aluminum Profiles Extruded Aluminum Heatsink

What makes black anodized aluminum heatsinks effective? Black anodized aluminum heatsinks work well because they handle heat efficiently. The anodized coating increases surface durability. This layer also improves corrosion resistance. Aluminum naturally conducts heat fast. The black color helps radiate heat better. These features keep electronic parts cooler.

Why pick extruded aluminum for heatsinks? Extrusion lets manufacturers create precise shapes. This process allows complex designs. More surface area means better heat distribution. Extruded aluminum profiles fit tight spaces. They balance performance and cost. This makes them popular for electronics and LED systems.

Do these heatsinks work in high-temperature environments? Yes. The anodized layer protects against oxidation. Aluminum handles heat without warping. These heatsinks manage steady thermal loads. They suit industrial machinery and power electronics. Proper sizing ensures they perform under stress.

Can these heatsinks be customized? Extruded aluminum allows easy customization. Profiles get cut to specific lengths. Holes or grooves get added for mounting. Fin density adjusts based on cooling needs. Colors match device designs. Custom shapes fit unique project requirements.

How do black anodized aluminum heatsinks compare to other materials? Aluminum weighs less than copper. It costs less too. Anodizing boosts aluminum’s natural benefits. Copper conducts heat slightly better. Aluminum wins for lightweight applications. It resists corrosion better than untreated metals. Most users find aluminum heatsinks offer the best balance.

What maintenance do these heatsinks need? They need almost no maintenance. Dust or debris should get cleaned occasionally. Use compressed air or a soft brush. The anodized layer prevents rust. Avoid harsh chemicals. Check for physical damage over time. Proper installation ensures long-term performance.

(Black Anodized Aluminum Heatsinks Good Performance Aluminum Profiles Extruded Aluminum Heatsink)

REQUEST A QUOTE

RELATED PRODUCTS

High Power Custom Aluminium Power Amplifier Rectangular Led Bar heatsink Profile Extrusion Radiators Aluminum Heat Sink

aluminum heatsink for three phase ssr solid state relay

Aluminium Profile Cooling Heatsink Product CNC machining

RDS Electronics-Customized size super cooling radiator 100*60*10MM aluminum heatsink

Industrial Aluminum Profile Anodized Heatsink 6061 6063 CNC Hollow Extruded Heat Sink