Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

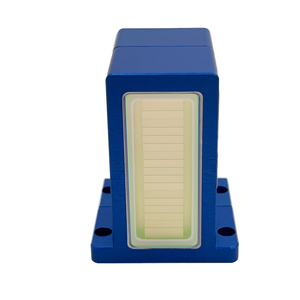

(Custom Precision Aluminum Profiles Aluminum Extruded Heat Sink, large aluminum heatsink)

Specifications of Custom Precision Aluminum Profiles Aluminum Extruded Heat Sink, large aluminum heatsink

Custom Precision Light Weight Aluminum Profiles Light Weight Aluminum Extruded Heat Sinks are engineered for effective thermal administration in high-performance applications. These warmth sinks usage state-of-the-art light weight aluminum alloys, understood for exceptional heat conductivity. The extrusion procedure develops complicated forms with limited resistances, making sure optimal surface for heat dissipation. Designs consist of finned frameworks, flat bases, or customized geometries tailored to particular needs.

These warmth sinks take care of high thermal tons in electronics, power products, LED systems, and commercial equipment. The aluminum product provides a lightweight service compared to copper, lowering total system weight. Plated coatings improve rust resistance and surface durability. Customized colors or layers are available for aesthetic or useful requirements.

Criterion dimensions range from small devices for little gadgets to large light weight aluminum heatsinks for sturdy applications. Measurements, fin density, and base thickness can be adjusted to match thermal demands. High-volume orders benefit from cost-effective manufacturing with constant quality. Model services allow screening prior to full-blown production.

Accuracy tooling makes sure harmony in automation. T-slots, channels, or installing holes can be integrated for easy setup. The extruded profiles preserve architectural integrity under mechanical tension or temperature level variations. Thermal simulations assist optimize styles for maximum efficiency.

These warmth sinks suit atmospheres needing passive air conditioning without external power. The all-natural convection layout reduces sound and energy usage. Compatibility with thermal interface materials like oil or pads improves performance. Customized layouts suit irregular areas or one-of-a-kind airflow patterns.

Longevity is focused on for long-lasting use in harsh conditions. Light weight aluminum withstands oxidation, expanding item life-span. Recyclable product sustains green manufacturing practices. Testing consists of thermal resistance checks, stress tolerance, and surface top quality examinations.

Applications cover automobile systems, renewable resource projects, telecommunications, and customer electronics. Engineers give assistance for layout changes or technical specifications. Lead times differ based on intricacy, with thrill choices for urgent needs. Bulk rates price cuts look for big orders.

Efficiency information sheets offer in-depth metrics on thermal conductivity, weight, and dimensional precision. Samples are offered for verification before acquisition. Product packaging alternatives safeguard items during shipping, with anti-static or moisture-resistant products as required.

(Custom Precision Aluminum Profiles Aluminum Extruded Heat Sink, large aluminum heatsink)

Applications of Custom Precision Aluminum Profiles Aluminum Extruded Heat Sink, large aluminum heatsink

Personalized accuracy aluminum accounts and extruded warmth sinks play a crucial role in taking care of heat in several sectors. These elements are widely used in electronic devices, auto systems, renewable energy jobs, and commercial machinery. Their layout concentrates on efficiently transferring warmth away from sensitive components, making sure gadgets run dependably under heats.

Aluminum is the key product for these warmth sinks. Aluminum provides a strong balance of lightweight buildings, exceptional thermal conductivity, and resistance to deterioration. This makes it optimal for applications where weight cost savings issue, like in electrical automobiles or aerospace devices. Custom-made forms allow these warm sinks to fit details areas, making the most of surface for better warmth dissipation.

Huge light weight aluminum heat sinks manage higher thermal tons. They are common in power electronic devices, LED lights systems, and high-performance computing. The extrusion procedure develops intricate geometries with fins or networks, improving air flow and cooling effectiveness. Producers often change styles using CNC machining or boring to satisfy precise requirements.

In the electronic devices sector, these warm sinks secure parts like CPUs, GPUs, and power converters from overheating. Automotive applications include cooling battery packs and inverters in electric autos. Renewable resource systems, such as solar inverters, rely on aluminum warmth sinks to keep performance in extreme outside environments. Industrial equipment uses them to cool down electric motor drives, lasers, and welding tools.

Personalized precision extrusion allows for tight resistances. This ensures components integrate seamlessly into settings up without additional modifications. The ability to create huge volumes rapidly makes extruded aluminum affordable for mass production. Surface area treatments like plating include longevity and enhance warmth radiation.

These heat sinks assistance development in innovation by making it possible for smaller, more effective devices. Their versatility meets the needs of developing markets, from customer electronic devices to heavy equipment. The mix of performance, personalization, and cost makes certain light weight aluminum stays a top selection for thermal management options.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Custom Precision Aluminum Profiles Aluminum Extruded Heat Sink, large aluminum heatsink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Custom Precision Aluminum Profiles Aluminum Extruded Heat Sink, large aluminum heatsink

What are custom precision aluminum profiles aluminum extruded heat sinks?

These heat sinks are parts made from aluminum. They are designed to manage heat in electronic devices. The process involves shaping aluminum through extrusion. This creates complex shapes that fit specific needs. Custom designs ensure the heat sink matches exact requirements for size, shape, performance.

Why choose aluminum for large heat sinks?

Aluminum is lightweight and conducts heat well. It resists corrosion and lasts long. Extruding aluminum is cost-effective for large sizes. The material bends easily into detailed shapes. This makes it ideal for custom heat sinks in industries like electronics or automotive.

Where are large aluminum heat sinks commonly used?

They are found in electronics, LED lighting, power supplies, automotive systems. Devices generating high heat need efficient cooling. Large heat sinks handle bigger thermal loads. They are used in servers, industrial machinery, renewable energy systems. Their size and design prevent overheating in critical applications.

Can custom aluminum heat sinks handle unique design requirements?

Yes. The extrusion process allows precise customization. Designers adjust dimensions, fin density, surface area. Special features like grooves or mounting holes are added. Custom finishes or coatings improve performance. Manufacturers work with clients to meet exact technical or aesthetic needs.

How durable are extruded aluminum heat sinks?

Aluminum naturally resists rust and environmental damage. Extruded designs maintain structural integrity under stress. They handle high temperatures without warping. Anodizing or powder coating adds extra protection. These heat sinks last years in harsh conditions. Regular maintenance is minimal.

What factors affect the performance of large aluminum heat sinks?

Surface area matters. More fins or ridges improve heat dissipation. Material purity impacts conductivity. Proper airflow around the heat sink is critical. Installation quality ensures contact with the heat source. Design alignment with the device’s thermal load prevents inefficiency.

(Custom Precision Aluminum Profiles Aluminum Extruded Heat Sink, large aluminum heatsink)

REQUEST A QUOTE

RELATED PRODUCTS

High Performance Custom Aluminum Extrusion Profile Heat Sink Extruded Semiconductor Industry Cooler HeatSink

High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry

CNC machined aluminum profile extruded heat sink T type extrusion custom electronic radiator standard heatsink

Custom Cold Forged CXB 3590 Aluminum LED Pin Heatsink 150mm

CNC machining Aluminum 3D Printer Heatsink Compatible with V6 J-Head Extruder Hotend Bowden – Short Heat Sink M6