Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

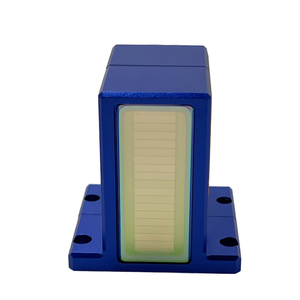

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(aluminum heatsink for three phase ssr solid state relay)

Specifications of aluminum heatsink for three phase ssr solid state relay

The aluminum heatsink designed for three-phase SSR (Solid State Relay) applications is engineered to efficiently dissipate heat generated during high-power switching operations, ensuring optimal performance and longevity of the relay. Constructed from high-grade aluminum alloy (typically 6063-T5 or similar), the heatsink combines lightweight properties with excellent thermal conductivity (approximately 180-200 W/m·K) to manage heat effectively. Its design features an array of fins that maximize surface area, enhancing airflow and heat dissipation through natural or forced convection.

Dimensions vary based on application requirements, but standard sizes range from 150 mm x 100 mm x 40 mm (LxWxH) to larger profiles for heavy-duty use. The heatsink’s weight typically falls between 500-1000 grams, balancing durability and ease of installation. Mounting holes are precision-drilled to align with standard three-phase SSR footprints, ensuring secure attachment using M4 or M5 screws. The base plate thickness (usually 8-12 mm) ensures even heat distribution from the SSR to the fins.

Thermal resistance is a critical specification, with values between 0.5°C/W to 1.5°C/W depending on the heatsink size and design. This ensures the SSR junction temperature remains within safe limits, even under continuous loads. The operating temperature range is -40°C to 150°C, suitable for industrial environments. Surface treatment includes anodization (black or natural silver) to improve corrosion resistance and thermal emissivity.

Compatibility extends to SSRs with current ratings of 25A to 150A, though sizing must align with the relay’s power dissipation needs. For optimal performance, thermal interface materials (e.g., silicone pads or thermal paste) are recommended between the SSR and heatsink. Installation guidelines emphasize proper airflow clearance (min. 50 mm around fins) and orientation to leverage natural convection. In high-ambient-temperature scenarios, auxiliary cooling (fans) may be required.

Compliant with RoHS and REACH standards, the heatsink is ideal for industrial automation, motor controls, and power distribution systems. Key benefits include reduced thermal stress on SSRs, extended component lifespan, and prevention of overheating-related failures. Always verify compatibility with specific SSR models and operational conditions before deployment.

(aluminum heatsink for three phase ssr solid state relay)

Applications of aluminum heatsink for three phase ssr solid state relay

Aluminum heatsinks are critical components in managing the thermal performance of three-phase solid-state relays (SSRs), which are widely used in high-power industrial and commercial applications. Three-phase SSRs control electrical loads by switching currents without mechanical contacts, generating significant heat during operation. Efficient heat dissipation is essential to maintain reliability, prevent overheating, and extend the lifespan of these devices. Aluminum’s high thermal conductivity, lightweight nature, and cost-effectiveness make it an ideal material for heatsinks in these systems.

In industrial automation, three-phase SSRs regulate machinery such as conveyor belts, pumps, and assembly lines. Continuous operation under heavy loads leads to heat accumulation, which aluminum heatsinks effectively dissipate, ensuring stable performance and minimizing downtime. Motor control systems also rely on SSRs for smooth acceleration and deceleration of three-phase motors. The high inrush currents during motor startups produce substantial heat, and aluminum heatsinks maintain optimal temperatures, safeguarding both the SSR and motor from thermal damage.

HVAC systems utilize three-phase SSRs to manage compressors and fans. Consistent thermal management via aluminum heatsinks prevents overheating in confined spaces, enhancing energy efficiency and system longevity. In renewable energy applications, such as solar inverters and wind turbine controllers, SSRs handle fluctuating power loads. Aluminum heatsinks provide passive cooling, crucial for maintaining efficiency in outdoor environments where reliability is paramount.

Power distribution panels and industrial heaters employ three-phase SSRs to manage high-voltage circuits. The heatsinks’ ability to disperse heat across extended periods ensures uninterrupted operation and reduces the risk of SSR failure. Aluminum’s corrosion resistance and durability further make it suitable for harsh environments, including humid or chemically exposed settings.

The design of aluminum heatsinks, often featuring finned structures or extruded profiles, maximizes surface area for improved heat dissipation. This passive cooling solution eliminates the need for fans, reducing maintenance and noise. By integrating aluminum heatsinks, three-phase SSRs achieve enhanced thermal stability, operational efficiency, and safety across diverse applications, from manufacturing to green energy systems.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality aluminum heatsink for three phase ssr solid state relay, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of aluminum heatsink for three phase ssr solid state relay

What is the purpose of an aluminum heatsink for a three-phase SSR? Aluminum heatsinks absorb and dissipate heat generated by three-phase solid-state relays during operation. SSRs switch high currents, which produces thermal energy. Without a heatsink, the relay could overheat, leading to premature failure or unsafe operation. The heatsink’s fins increase surface area to improve airflow and cooling efficiency, ensuring stable performance.

Why is aluminum commonly used for SSR heatsinks? Aluminum offers an optimal balance of thermal conductivity, weight, and cost. It efficiently transfers heat away from the SSR while remaining lightweight and corrosion-resistant. Compared to copper, aluminum is more affordable and easier to manufacture into complex shapes. Anodized aluminum finishes further enhance durability and heat dissipation, making it ideal for industrial environments.

How do I choose the right size heatsink for a three-phase SSR? The heatsink size depends on the SSR’s load current, ambient temperature, and airflow. Higher currents or hotter environments require larger heatsinks or added cooling (e.g., fans). Check the SSR’s datasheet for thermal resistance values and match them to the heatsink’s rating. Undersized heatsinks risk overheating, while oversized ones add unnecessary bulk and cost.

Do I need thermal paste or pads when installing the heatsink? Yes. Thermal interface materials (paste, pads, or grease) fill microscopic gaps between the SSR and heatsink, improving heat transfer. Apply a thin, even layer of paste or use a pre-cut pad to ensure maximum contact. Avoid over-tightening mounting hardware, as this can damage the SSR or warp the heatsink, reducing efficiency.

Can a heatsink work without forced airflow (fans)? Passive cooling (no fans) works if the heatsink is adequately sized for the SSR’s power dissipation and ambient conditions. In enclosed spaces or high-temperature environments, active cooling (fans) may be necessary. Monitor temperatures during initial operation—if the SSR exceeds its rated temperature, add forced airflow or upgrade the heatsink. Regular maintenance (e.g., dust removal) also ensures optimal performance.

(aluminum heatsink for three phase ssr solid state relay)

REQUEST A QUOTE

RELATED PRODUCTS

TCH Factory High Quality heatsinks Custom heatsink Aluminum Profile Extrusion Service Heat Sink

Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth Heat Sink

Anodized Deep Processing Sunflower Close Tooth Lamp Heatsink Round Led Aluminum Profile Extrusion Heat Sink

Custom CNC aluminum extrusion profiles black anodizing custom-made LED radiator aluminum heatsink

thyristor water-cooling heatsinks SS14