Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

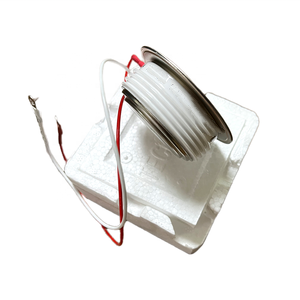

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink)

Specifications of best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink

The very best style graphics card heatsinks combine high-performance materials with innovative engineering. These heatsinks use extruded 55mm light weight aluminum or copper to balance heat dissipation and toughness. Aluminum heatsinks are lightweight and cost-effective. They work well for modest cooling demands. Copper heatsinks provide remarkable thermal conductivity. They manage intense warm tons more effectively. Both materials go through accuracy extrusion to develop dense fin selections. This takes full advantage of surface for better air movement.

The 55mm density makes sure optimum warmth absorption. It fits conventional graphics card formats. The compact design stays clear of mass while preserving cooling power. Fins are spaced very closely to catch warmth. They guide it away from critical parts. Base plates are machined level for complete call with the GPU. This gets rid of spaces that decrease thermal transfer.

Copper heatsinks typically consist of nickel plating. This protects against oxidation and keeps the surface area smooth. Aluminum heatsinks make use of plated coatings. These boost deterioration resistance and durability. Both options assistance passive or energetic cooling setups. Individuals can add followers for additional airflow. The layout stays secure under heats. It withstands warping with time.

Setup is uncomplicated. Pre-drilled holes match most GPU installing factors. Thermal pads or paste can be used easily. The heatsinks deal with solitary or multi-card configurations. They preserve reduced noise degrees also under tons. This makes them excellent for gaming gears or workstations.

Extruded light weight aluminum heatsinks fit budget builds. They deliver reputable air conditioning without high costs. Copper heatsinks target high-end systems. They master overclocking or extended use circumstances. Both kinds prioritize effective warm circulation. They prevent hotspots that harm hardware.

The fins are angled to guide air movement naturally. This decreases dependence on outside followers. Surface area treatments boost warm radiation. They assist dissipate power much faster. Upkeep is easy. Dirt can be rubbed out without disassembly.

These heatsinks sustain contemporary GPUs from major brand names. Compatibility covers mid-range to flagship models. Modification choices include different fin thickness or heights. Customers tailor the heatsink to their certain needs.

Durability examinations validate long-term efficiency. Materials stand up to duplicated thermal cycles. Architectural stability remains undamaged after years of usage. The heatsinks meet industry criteria for safety and performance. They make certain consistent cooling under differing work.

Performance gains consist of lower GPU temperatures and extended equipment life. Energy consumption goes down as cooling down boosts. System stability enhances throughout demanding tasks. These heatsinks are a practical upgrade for any construct.

(best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink)

Applications of best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink

Style graphics card heatsinks made from extruded 55mm light weight aluminum or copper materials offer important roles in taking care of warmth for high-performance systems. These elements make sure steady operation by moving warmth far from sensitive components. Extruded light weight aluminum heatsinks are light-weight and affordable. They match applications where budget plan and weight matter. Copper heatsinks offer exceptional warmth transfer performance. They handle intense thermal loads much better. Both types adapt to various requirements throughout markets.

Pc gaming Computers and high-end workstations rely on these heatsinks. Modern GPUs create significant heat during extended use. Light weight aluminum heatsinks with 55mm accounts equilibrium cooling and room restraints. They fit portable builds without giving up efficiency. Copper heatsinks work in overclocked systems. They avoid overheating during extreme processing tasks like 3D rendering or AI calculations. Servers and data facilities use these services also. Steady temperature levels lower equipment failing threats.

Home entertainment systems benefit from quiet cooling. Aluminum heatsinks pair with low-noise fans for media centers. Copper variants sustain passive air conditioning setups. They eliminate follower sound completely. Industrial equipments make use of extruded heatsinks for resilience. Extreme settings require corrosion-resistant products. Aluminum resists oxidation. Copper preserves performance under continuous stress and anxiety.

Cryptocurrency mining rigs rely on effective thermal monitoring. Several GPUs run continuously. Copper heatsinks take care of warm buildup better. They expand equipment life-span. Aluminum choices lower total configuration expenses. Crossbreed styles combine both metals. Light weight aluminum bases with copper fins maximize heat dissipation.

Customizable extruded profiles enable tailored remedies. 55mm aluminum heatsinks adjust to details GPU formats. Copper variations satisfy high-wattage applications. Both materials incorporate with heat pipelines or fluid cooling. Customers focus on performance or budget plan. Light weight aluminum matches conventional builds. Copper targets enthusiasts and specialists.

Easy air conditioning systems use copper’s all-natural conductivity. Energetic arrangements with fans work well with aluminum. Warm distribution remains also. Thermal strangling decreases. Component longevity boosts.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink

The best design graphics card heatsinks use extruded 55mm aluminum or copper. These materials balance cooling efficiency and cost. Here are common questions about them.

Why is 55mm a common size for heatsinks? Graphics cards need compact cooling. A 55mm thickness fits most card designs. It allows enough surface area to dissipate heat without adding bulk. This size works for mid-range to high-end GPUs.

Aluminum or copper—which is better? Copper conducts heat faster. It cools more effectively in high-performance systems. Copper costs more. Aluminum is lighter and cheaper. It works well for standard gaming or office setups. Many heatsinks combine both—copper bases with aluminum fins.

How do extruded heatsinks improve cooling? Extrusion creates precise shapes. This increases surface area for heat dissipation. The process ensures tight contact between the heatsink and GPU. Better contact means heat transfers faster. Extruded designs reduce hotspots on the card.

Are these heatsinks easy to install? Most use standard mounting brackets. Check compatibility with your GPU model. Apply thermal paste between the heatsink and GPU. Tighten screws evenly. Improper installation causes uneven pressure. This reduces cooling efficiency. Follow the manufacturer’s guide.

What affects heatsink performance? Material quality matters. Thicker fins or more heat pipes improve cooling. Airflow inside the case is critical. Dust buildup blocks heat escape. Clean heatsinks regularly. Thermal paste quality impacts heat transfer. Replace dried or low-quality paste.

Maintenance keeps heatsinks effective. Remove dust every few months. Check thermal paste yearly. Ensure fans spin smoothly. Monitor GPU temperatures using software. High temps signal cooling issues. Address problems quickly to avoid hardware damage.

(best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink)

REQUEST A QUOTE

RELATED PRODUCTS

Aluminum Heatsink 8.8×8.8x5mm Electronic Chip Cooling Radiator Cooler for CPU,RAM,GPU,A4988 Chipset Heat Sink

CNC machined aluminum profile extruded heat sink T type extrusion custom electronic radiator standard heatsink

Customized Precision Water Cooling Amplifier Heatsink Aluminium Heatsink

High Precision Custom High Performance CNC Extruded Heatsink Anodizing Aluminum Heatsink For LED Street Light

Hot Round LED Heatsink Parts Aluminum Heatsink for LED industrial