Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

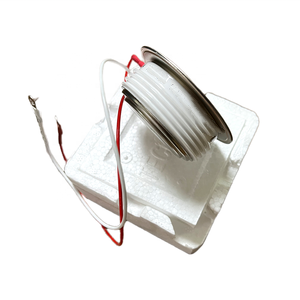

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(Chengdacai 6061 6063 Custom Anodized Flat Heat Sink Extrusion Aluminium Heatsink Aluminum Heat Radiator)

Specifications of Chengdacai 6061 6063 Custom Anodized Flat Heat Sink Extrusion Aluminium Heatsink Aluminum Heat Radiator

The Chengdacai 6061 and 6063 Custom Anodized Apartment Heat Sink Extrusion Aluminium Heatsink is crafted for high-performance thermal administration in industrial, electronic, and mechanical applications. Created from costs 6061 and 6063 aluminum alloys, this heatsink incorporates longevity with remarkable warm dissipation. The 6061 alloy uses exceptional stamina, weldability, and machinability, ideal for architectural elements, while the 6063 alloy supplies improved thermal conductivity (up to 210 W/m · K) and smoother surface finishes, optimized for efficient heat transfer.

Custom-made extrusion accounts enable customized designs to meet specific thermal and spatial needs. The heatsink functions level, finned, or crossbreed geometries, with fin elevations varying from 5 mm to 100 mm and base thicknesses from 2 mm to 20 mm. Accuracy extrusion makes sure tight tolerances ( ± 0.1 mm) for consistent performance.

Anodization enhances corrosion resistance, surface area solidity, and visual charm. The Type II or Type III anodized layer (15– 25 µm thick) supplies optional color personalization (black, silver, gold) and boosts emissivity for radiative cooling. The surface finish attains a roughness (Ra) of ≤ 0.8 µm, decreasing thermal interface resistance.

Developed for passive or forced-air cooling, the heatsink operates efficiently in temperature levels from -50 ° C to 200 ° C. Its light-weight light weight aluminum building (thickness: 2.7 g/cm ³) decreases system lots while keeping structural honesty. Suitable with thermal interface materials (TIMs), it incorporates perfectly right into assemblies for electronic devices, LED lighting, power supplies, auto systems, and renewable energy equipment.

Criterion sizes range from 100 mm to 6000 mm, with personalized cuts readily available. Optional exploration, touching, or CNC machining allows direct placing for parts like CPUs, IGBTs, or power semiconductors. RoHS and REACH conformity guarantee ecological safety.

This heatsink is perfect for applications demanding dependability, modification, and high thermal efficiency. Its anodized surface withstands oxidation and wear, making sure long life in rough environments. For tasks calling for specific thermal options, the Chengdacai heatsink provides efficiency, flexibility, and resilience.

(Chengdacai 6061 6063 Custom Anodized Flat Heat Sink Extrusion Aluminium Heatsink Aluminum Heat Radiator)

Applications of Chengdacai 6061 6063 Custom Anodized Flat Heat Sink Extrusion Aluminium Heatsink Aluminum Heat Radiator

Chengdacai 6061 and 6063 Custom Anodized Flat Warm Sink Extrusion Aluminium Heatsink Light Weight Aluminum Heat Radiator is a high-performance thermal administration option created to dissipate warm successfully sought after applications. Crafted from premium 6061 and 6063 light weight aluminum alloys, these heatsinks integrate light-weight longevity with superb thermal conductivity, making them ideal for sectors where temperature control is vital. The custom extrusion procedure permits accurate tailoring of dimensions, fin thickness, and geometry to fulfill certain thermal and spatial demands, guaranteeing optimal performance in diverse environments.

The anodized surface treatment enhances rust resistance, surface area solidity, and aesthetic allure while boosting warm dissipation. This safety layer also enables color personalization, making the heatsinks suitable for applications where visual uniformity issues. The level extrusion style takes full advantage of surface area call with heat-generating parts, promoting quick warm transfer and stable operation.

** Applications ** cover numerous industries:

– ** Electronic devices & Computer **: Made Use Of in CPUs, GPUs, power products, and LED drivers to avoid overheating and expand element life-span.

– ** LED Lighting **: Important for high-power LED fixtures and streetlights, ensuring brightness consistency and thermal security.

– ** Automotive **: Integrated right into electric automobile (EV) battery systems, onboard chargers, and inverters to handle warmth in compact rooms.

– ** Renewable resource **: Released in solar inverters and wind turbine controllers to maintain performance under fluctuating loads.

– ** Industrial Machinery **: Sustains motor drives, laser systems, and CNC equipment by reducing thermal stress and anxiety throughout extended procedures.

– ** Telecommunications **: Safeguards 5G base stations, routers, and web servers from heat-related downtime.

Chengdacai’s heatsinks are valued for their accuracy engineering, versatility, and compliance with industry criteria. Whether for high-power electronic devices, sturdy commercial setups, or consumer-facing products, these plated light weight aluminum warm radiators supply integrity, long life, and cost-efficient thermal monitoring. Their adaptability makes them a best choice for designers seeking scalable solutions to intricate warm dissipation obstacles.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Chengdacai 6061 6063 Custom Anodized Flat Heat Sink Extrusion Aluminium Heatsink Aluminum Heat Radiator, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Chengdacai 6061 6063 Custom Anodized Flat Heat Sink Extrusion Aluminium Heatsink Aluminum Heat Radiator

What is the difference between 6061 and 6063 aluminum alloys in Chengdacai heat sinks?

6061 aluminum offers higher strength and is ideal for applications requiring structural durability, while 6063 provides superior thermal conductivity and smoother surface finishes, making it better suited for heat dissipation. Chengdacai uses 6063 for optimized thermal performance in standard heat sinks but offers 6061 for projects needing extra mechanical strength.

Why is anodizing important for aluminum heat sinks?

Anodizing enhances corrosion resistance, improves surface hardness, and increases thermal emissivity (heat radiation efficiency). It also allows for color customization, which can aid in branding or aesthetic matching. The process doesn’t significantly alter the aluminum’s inherent thermal conductivity, ensuring the heat sink remains efficient while gaining durability and visual appeal.

What customization options are available for Chengdacai heat sinks?

Chengdacai provides custom extrusion profiles, lengths, thicknesses, hole patterns, and surface finishes (e.g., matte, gloss). Anodizing colors (black, silver, gold, etc.) and additional CNC machining for precise component integration are also offered. Custom designs are tailored to fit specific thermal, spatial, or mechanical requirements of devices like CPUs, LED systems, or industrial machinery.

In which applications are these heat sinks commonly used?

These heat sinks are widely used in electronics (CPUs, GPUs), LED lighting, power supplies, automotive systems (EV batteries, inverters), and industrial equipment. Their high thermal efficiency and customizable designs make them suitable for any scenario requiring passive cooling, especially where space constraints or harsh environments demand reliability.

How durable and maintenance-free are anodized aluminum heat sinks?

Anodized heat sinks are highly durable, resisting scratches, corrosion, and UV degradation. They require minimal maintenance—occasional dusting or gentle cleaning with a mild detergent suffices. Avoid abrasive tools to preserve the anodized layer. Properly installed, they maintain performance for years, even in high-temperature or humid conditions, ensuring long-term reliability.

(Chengdacai 6061 6063 Custom Anodized Flat Heat Sink Extrusion Aluminium Heatsink Aluminum Heat Radiator)

REQUEST A QUOTE

RELATED PRODUCTS

Chengdacai 6061 6063 Custom Anodized Flat Heat Sink Extrusion Aluminium Heatsink Aluminum Heat Radiator

Heatsink

best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink

Square Extruded Aluminum Heatsink with Fan for Computer CPU

RDS Electronics-Customized size super cooling radiator 100*60*10MM aluminum heatsink