Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

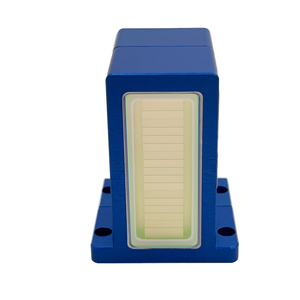

(Custom Design Square heatsink Anodized Extruded Large Aluminum Extrusion Profile Heat Sink)

Specifications of Custom Design Square heatsink Anodized Extruded Large Aluminum Extrusion Profile Heat Sink

This custom-made design square heatsink is constructed for high-performance cooling in commercial and electronic applications. It uses plated extruded aluminum for sturdiness and heat dissipation. The material is 6063-T5 or 6061-T6 aluminum alloy, picked for thermal conductivity and structural toughness. Requirement sizes vary from 40mm x 40mm to 300mm x 300mm in base size. Custom dimensions are available. The size can be adjusted from 50mm to 1500mm to fit specific project demands. Surface anodization is available in natural silver, black, or personalized colors. This layer protects versus rust and wear. It also enhances radiant heat efficiency. The extrusion procedure enables complex fin styles. Fins are spaced in between 3mm and 12mm apart. Fin elevations differ from 10mm to 80mm. This design maximizes area for far better airflow and warm transfer. The base density is flexible between 4mm and 20mm. Thicker bases handle higher thermal loads. Installing options include pre-drilled holes, grooves, or threaded inserts. Opening patterns match typical part designs. Resistances are tight, with ± 0.1 mm precision for crucial measurements. Monotony is kept within 0.05 mm per 100mm length. The coating is smooth, with a surface area roughness under Ra 1.6 μm. This ensures appropriate contact with warmth sources. The heatsink works with passive cooling or forced-air systems. It supports add-on of fans or liquid air conditioning modules. Thermal resistance varieties from 0.15 ° C/W to 1.2 ° C/W. Performance depends on dimension, style, and air movement. Checking includes thermal imaging and stress decrease analysis. Each set undergoes high quality look for dimensional accuracy and coating consistency. Applications consist of power electronic devices, LED lighting, motor drives, and CPU cooling. It fits web server racks, renewable energy systems, and automotive components. Weight is reduced via hollow networks in the extrusion profile. This keeps strength while cutting mass by approximately 30%. Personalized logos or part numbers can be included throughout anodizing. Product packaging choices include anti-scratch movies or safety foam. Lead times differ from 2 weeks for typical layouts to 6 weeks for totally custom orders. Samples are available for thermal screening before bulk production.

(Custom Design Square heatsink Anodized Extruded Large Aluminum Extrusion Profile Heat Sink)

Applications of Custom Design Square heatsink Anodized Extruded Large Aluminum Extrusion Profile Heat Sink

Custom-made style square heatsinks made from plated extruded huge aluminum extrusion accounts serve vital functions in handling heat across industries. These parts transfer heat away from delicate tools. They avoid getting too hot. They make certain systems run efficiently. Their style adapts to certain requirements. They fit special layouts. They take care of high thermal lots.

Electronic devices count on these heatsinks. High-power devices create excess heat. Processors, power transistors, LED drivers require cooling. Square forms take full advantage of surface area. Warmth spreads much faster. Anodized surfaces stand up to rust. They last longer in damp or rough setups. Extruded aluminum allows intricate forms. Networks or fins enhance airflow. Heat dissipates properly.

Industrial machinery uses these heatsinks. Motors, transformers, power supplies generate warmth. Big light weight aluminum profiles soak up more energy. Customized dimensions fit limited spaces. Plating adds longevity. It deals with chemicals or abrasion. Temperature security prevents downtime. Machines run longer without failing.

LED lighting systems take advantage of these solutions. High-brightness LEDs generate considerable heat. Thermal monitoring expands life expectancy. Square profiles disperse heat uniformly. Plated coatings shield versus oxidation. Customized creates match fixture designs. They maintain slim, visual forms while cooling down effectively.

Electric automobiles and auto tech make use of these heatsinks. Battery packs, inverters, billing systems need air conditioning. Light weight aluminum’s light-weight homes reduce car load. Extruded profiles allow small integration. Anodized surface areas withstand roadway salts or dampness. Warmth regulation prevents battery destruction. Performance stays consistent.

Renewable energy systems rely on these elements. Solar inverters, wind turbine controllers require reliable air conditioning. Huge extrusion accounts manage high thermal lots. Customized forms fit uneven spaces. Plated light weight aluminum withstands weathering. Systems run effectively in outdoor settings. Power production stays steady.

Telecommunications devices uses these heatsinks. Web servers, base stations, amplifiers produce warmth. Custom designs maximize area in rooms. Square profiles enhance warm transfer. Anodized finishes avoid corrosion in exposed installments. Signal reliability enhances with temperature level control.

These heatsinks combine feature and versatility. Light weight aluminum extrusion permits accurate tailoring. Plating increases durability. Applications cover electronics, industry, lights, automobile, power, telecom. Each sector gains from effective thermal administration. Devices lasts much longer. Efficiency stays high.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Custom Design Square heatsink Anodized Extruded Large Aluminum Extrusion Profile Heat Sink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Custom Design Square heatsink Anodized Extruded Large Aluminum Extrusion Profile Heat Sink

What applications suit the Custom Design Square Heatsink?

This heatsink works in electronics, LED lighting, power supplies, industrial machinery. It handles high thermal loads. Common uses include cooling computer components, amplifiers, automotive systems. The square shape fits tight spaces.

Can the heatsink design be customized?

Yes. The design adapts to specific thermal needs. Adjust dimensions, fin density, material thickness. The extrusion process creates complex shapes. Custom holes, grooves, surface finishes are possible. Provide project details for tailored solutions.

Why choose an anodized aluminum heatsink?

Anodization improves corrosion resistance. It increases surface hardness. The finish lasts longer in harsh environments. Color options match branding or aesthetic needs. Anodizing does not block heat transfer.

How large and heavy can these heatsinks get?

Extruded aluminum profiles support big sizes. Maximum dimensions depend on extrusion equipment. Typical lengths reach several meters. Weight stays low due to aluminum’s lightness. Structural support is added for extra-large designs.

Does this heatsink perform better than others?

Aluminum’s high thermal conductivity helps. The square shape increases surface area. Extruded fins improve airflow. Custom designs target specific heat issues. Performance beats standard off-the-shelf options. Testing ensures it meets thermal goals.

(Custom Design Square heatsink Anodized Extruded Large Aluminum Extrusion Profile Heat Sink)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Precision Water Cooling Amplifier Heatsink Aluminium Heatsink

High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry

Custom 6063 Anodized Enclosure Aluminum Extrusion Heat Sink,Cnc Milling Aluminum Extrusion Heatsink

High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink

High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink