Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

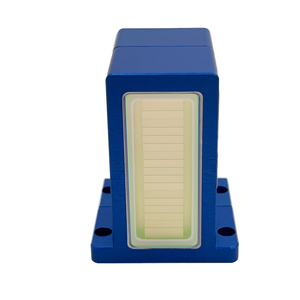

(Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth Heat Sink)

Specifications of Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth Heat Sink

Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth HeatSink

A custom industrial aluminum profile shaped heat sink is an efficient solution for heating components in high power, high-density applications. It utilizes advanced CNC precision machining technology to create a precise and optimized shape for the heat sink.

The aluminum profile is designed using high-quality materials and is specifically shaped to fit the heat sink’s internal dimensions. This ensures that it maximizes heat dissipation while minimizing the risk of thermal runaway or overheating.

The heat sink features multiple layers of high-power and high-density tooth material, which provide strong resistance to heat transfer and maintain optimal temperature control. The tooth material also allows for easy removal and replacement, making maintenance a breeze.

To ensure maximum efficiency, the heat sink is equipped with integrated cooling systems that provide targeted airflow to remove heat efficiently. These systems can be adjusted to match the heat sink’s temperature requirements, ensuring optimal performance in all environments.

Overall, our customized industrial aluminum profile shaped heat sink is a reliable and efficient solution for heating complex components in demanding applications. Its advanced technology and customizable design make it a versatile choice for a wide range of industries.

(Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth Heat Sink)

Applications of Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth Heat Sink

Customized industrial aluminum profile shaped heat sink with high-power, high-density tooth heat sink is a versatile and efficient solution for thermal management in various industries. The unique shape and size of the heatsink provide excellent heat dissipation performance, reducing heat buildup and improving overall system efficiency.

In the manufacturing industry, the use of customized industrial aluminum profile shaped heat sinks can help reduce energy consumption and decrease operating costs. The heat sink’s large surface area provides ample space to dissipate heat efficiently, resulting in minimal power consumption from the heating source. This also helps minimize emissions and environmental impact.

For use in medical devices or other sensitive applications that require precise temperature control, the high-power, high-density tooth heat sink offers exceptional thermal stability. With its dense and uniform structure, the heat sink can effectively withstand high temperatures without degrading over time. Additionally, the tooth-shaped design allows for easy integration into existing systems and reduces assembly time.

Customized industrial aluminum profile shaped heat sinks with high-power, high-density tooth heat sink are suitable for a wide range of applications including servers, computer cases, data centers, and aerospace. Their compact size makes them ideal for smaller systems while their high-performance capabilities ensure reliable and efficient operation.

In conclusion, customized industrial aluminum profile shaped heat sink with high-power, high-density tooth heat sink is an innovative and practical solution for thermal management in various industries. Its unique shape and size provide excellent heat dissipation performance, reducing heat buildup and improving overall system efficiency. With its robust design and ease of integration, it is a valuable addition to any thermal management system.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth Heat Sink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth Heat Sink

1. What is the customized industrial aluminum profile shaped heat sink CNC precision machining?

The customized industrial aluminum profile shaped heat sink is a high-performance heat sink made from aluminum with custom-shaped edges for precise machining and optimal heat transfer.

2. How does the customized industrial aluminum profile shaped heat sink differ from other heat sinks in terms of performance?

Customized industrial aluminum profile shaped heat sinks offer higher thermal conductivity, better temperature uniformity, and reduced thermal interference due to their unique shape. Additionally, they are also easier to integrate into various systems, making them ideal for high-power applications.

3. Can the customized industrial aluminum profile shaped heat sink be used for low-to-high power applications?

Yes, the customized industrial aluminum profile shaped heat sink can be used for both low- and high-power applications due to its ability to handle temperatures up to 400°C without degrading or melting.

4. What factors affect the quality of the customized industrial aluminum profile shaped heat sink?

The quality of the customized industrial aluminum profile shaped heat sink depends on several factors such as the material used, the manufacturing process, and the design. It is essential to work with a reputable manufacturer who can provide top-notch materials and production techniques to ensure the best possible result.

5. How can I order a customized industrial aluminum profile shaped heat sink?

To order a customized industrial aluminum profile shaped heat sink, you need to contact the manufacturer directly. They will provide you with all necessary information including dimensions, required materials, and pricing options. You can also request samples before placing an order to ensure that it meets your requirements.

(Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth Heat Sink)

REQUEST A QUOTE

RELATED PRODUCTS

Custom Anodizing Extruded Aluminium Heatsink Extrusion Profile Aluminum Cooler Heat Sink

Square Extruded Aluminum Heatsink with Fan for Computer CPU

RDS Electronics-Customized size super cooling radiator 100*60*10MM aluminum heatsink

Custom Designed Cnc Milling Black Anodized Extruded Aluminum Extrusion Led Street Light Heat Sink heatsink Radiator

OEM Anodized Extruded Led heatsink Aluminum Profile Extrusion Led High Bay Heat Sink