Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

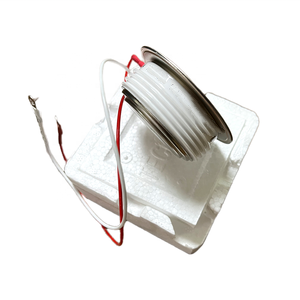

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

(High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink)

Specifications of High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink

The High Power CNC Extruded Enclosure Heatsink Account Radiator Cooler is crafted to supply premium thermal management for high-performance applications such as IGBT modules, cars and truck amplifiers, power electronics, and industrial equipment. Crafted from top-quality aluminum alloy (6063-T5), this heatsink integrates light-weight sturdiness with remarkable warm dissipation, making sure trustworthy operation sought after atmospheres. The extrusion process produces a thick fin framework, making the most of surface to successfully move warmth far from delicate elements. Precision CNC machining guarantees tight dimensional resistances and smooth surface areas, allowing seamless integration with gadgets and improving thermal call. The heatsink’s design includes a robust, one-piece extruded account that withstands buckling under high thermal tons, while its anodized surface area finish boosts rust resistance and durability. Available in conventional and custom-made lengths, the account can be tailored to fit specific demands. Trick requirements consist of a thermal conductivity rating of 180-200 W/m · K, making sure quick warm transfer, and a functioning temperature level variety of -50 ° C to 250 ° C for versatility across climates. The fin thickness (4-6 fins per inch) and base thickness (8-15mm) are maximized to balance airflow performance and structural honesty. Mounting alternatives include threaded holes, clips, or glue thermal pads for versatile setup. The extruded grooves and networks accommodate extra cooling options like followers or liquid air conditioning systems. With a flatness resistance of ± 0.1 mm, the base makes certain ideal contact with heat-generating elements, lessening thermal resistance. Ideal for auto audio systems, the heatsink protects against overheating in high-wattage amplifiers, making certain regular sound top quality. For industrial IGBT modules, it supports temperature level variations, prolonging part life expectancy. The radiator’s compact, light-weight design makes it appropriate for space-constrained applications without compromising cooling performance. Its environment-friendly, recyclable aluminum construction lines up with sustainability requirements. Personalized specifications include general measurements (width: 50-300mm, elevation: 20-150mm), fin height, and surface area therapies (all-natural, black, or tinted anodization). The heatsink is examined for vibration resistance and EMI protecting compatibility, making it a versatile remedy for automotive, renewable energy, and telecommunications industries. Backed by rigorous quality assurance, this heatsink provides an economical, high-efficiency cooling solution for high-power digital systems.

(High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink)

Applications of High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink

The High Power CNC Extruded Unit Heatsink Account Radiator Colder is a precision-engineered thermal administration service created for demanding applications where efficient warm dissipation is essential. Crafted from high-grade extruded aluminum, this heatsink integrates lightweight longevity with exceptional thermal conductivity, making it perfect for high-power digital systems. The CNC machining process makes certain precise dimensional precision, enabling seamless combination into complex settings up while maximizing area for optimal warm transfer. Its extruded profile allows for personalized layouts tailored to certain thermal and mechanical requirements, making certain trusted efficiency in diverse environments.

In vehicle applications, this heatsink is widely utilized to cool cars and truck amplifiers, particularly in high-wattage audio systems. By successfully dissipating warmth created during long term procedure, it avoids overheating, ensuring regular audio efficiency and extending the lifespan of amplifier components. Additionally, electric vehicles (EVs) count on these heatsinks to handle thermal lots in IGBT (Protected Entrance Bipolar Transistor) modules, which control power flow in inverters and electric motor drives. Efficient air conditioning right here is important for keeping efficiency and reliability in EV powertrains.

Industrial setups benefit from these heatsinks in motor drives, CNC machinery, and power supplies, where IGBTs and high-power semiconductors create significant warm. The durable light weight aluminum construction stands up to severe problems, while the extruded style boosts air movement, reducing downtime brought on by thermal failings. Renewable resource systems, such as solar inverters and wind turbine converters, likewise utilize these heatsinks to make sure secure procedure of power electronic devices under rising and fall loads.

Telecom facilities, including 5G base terminals and server farms, employs these radiators to cool high-density electronic components, protecting against data loss and hardware damage. The corrosion-resistant aluminum and personalized profiles make them suitable for both interior and outdoor installments.

In summary, this heatsink’s versatility spans automotive, industrial, renewable resource, and telecommunications fields, providing an affordable, durable service for thermal challenges. Its combination of CNC accuracy, squeezed out light weight aluminum efficiency, and adaptive design guarantees optimal performance, making it indispensable for modern high-power applications needing trustworthy cooling.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink

When purchasing a High Power CNC Extruded Enclosure Heatsink Profile Radiator Cooler for IGBT or Car Amplifier applications, customers often have questions about its design and performance. Here are five common FAQs answered directly:

**1. What materials are used in these heatsinks?**

The heatsinks are made from high-grade aluminum alloys, typically 6063-T5, known for excellent thermal conductivity (up to 180-200 W/m·K). Aluminum is lightweight, corrosion-resistant, and durable, making it ideal for heat dissipation in demanding environments like car amplifiers or industrial IGBT systems.

**2. Why choose a CNC extruded design?**

CNC extrusion ensures precise, complex profiles with tight tolerances, optimizing surface area for heat transfer. The extrusion process creates continuous fins or channels that maximize airflow, while CNC machining allows for custom shapes, mounting holes, or grooves to fit specific components. This combination guarantees efficient cooling and easy integration into existing setups.

**3. Are these heatsinks compatible with all car amplifiers or IGBT modules?**

Yes, but customization is key. These heatsinks are designed to be adaptable. You can specify dimensions, fin density, base thickness, and mounting options to match your amplifier’s size or IGBT module’s thermal load. Standard sizes are available, but most manufacturers offer tailored solutions for unique requirements.

**4. How do I maintain the heatsink?**

Aluminum heatsinks require minimal maintenance. Periodically clean dust or debris from the fins using compressed air or a soft brush to prevent airflow blockage. Avoid abrasive cleaners to protect the surface finish. For harsh environments, anodized finishes add extra corrosion resistance.

**5. What makes these heatsinks better than stamped or folded alternatives?**

Extruded aluminum heatsinks offer superior thermal performance due to their uniform structure and higher mass-to-surface-area ratio. CNC precision ensures better contact with heat-generating components, reducing thermal resistance. Unlike stamped metal, extruded profiles are stronger, more durable, and can handle higher continuous loads without warping, making them ideal for high-power applications like car audio systems or industrial electronics.

(High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink)

REQUEST A QUOTE

RELATED PRODUCTS

OEM Anodized Extruded Led heatsink Aluminum Profile Extrusion Led High Bay Heat Sink

Yudatech Copper Heatsink High Quality Customized Copper Skiving Fin Heatsink

WellSunFan China ODM Good thermal Heatsink OEM Custom Manufacturing Square Heatsink

Heatsink

best design graphics card heatsinks extruded 55mm aluminum heatsink copper heatsink