Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

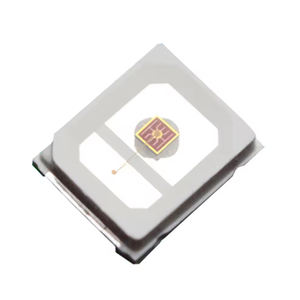

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

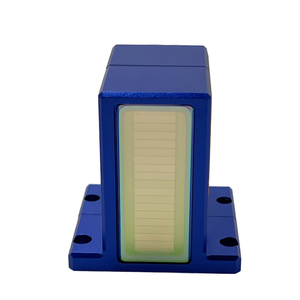

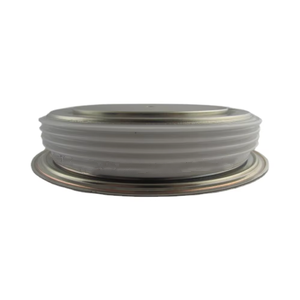

(thyristor water-cooling heatsinks SS14)

Specifications of thyristor water-cooling heatsinks SS14

The SS14 thyristor water-cooling heatsinks are engineered to supply reliable thermal monitoring for high-power thyristor applications, ensuring ideal efficiency and long life sought after commercial atmospheres. Constructed from state-of-the-art aluminum alloy, these heatsinks combine light-weight style with superior thermal conductivity. The primary feature is to dissipate warmth produced by thyristors, SCRs, and other power semiconductor tools, preserving steady operating temperatures also under constant load conditions.

** Trick Specifications: **.

– ** Product: ** Light weight aluminum alloy (6063-T5) with anti-corrosion surface therapy, ensuring longevity and resistance to coolant deterioration.

– ** Thermal Resistance: ** ≤ 0.03 ° C/W at a water flow price of 6 L/min, enabling efficient warm transfer from gadget to coolant.

– ** Coolant Circulation Price: ** Suggested functional variety of 2– 8 litres per min (L/min) for balanced performance and pressure management.

– ** Max Operating Pressure: ** 0.4 MPa (4 bar), compatible with common industrial water-cooling systems.

– ** Power Dissipation Capacity: ** Supports approximately 15 kW per unit, appropriate for high-current thyristor modules in rectifiers, inverters, and electric motor drives.

– ** Inlet/Outlet Connections: ** Requirement G1/2 or G3/4 threaded ports, versatile to many pipes setups.

– ** Dimensions: ** Personalized baseplates (regular size: 200 mm x 150 mm x 50 mm) to match thyristor impacts, with installing openings for protected add-on.

– ** Weight: ** Roughly 2.5 kg (varies based upon arrangement).

– ** Running Temperature Range: ** -40 ° C to +120 ° C, making sure integrity in extreme problems.

** Applications: ** Suitable for use in electrical arc heating systems, welding equipment, traction systems, and renewable energy converters where water cooling is chosen over air cooling for its density and higher heat dissipation efficiency. The SS14’s layout reduces thermal stress and anxiety on thyristors, reducing failing threats and downtime.

** Advantages: **.

– Low-maintenance style with no relocating parts, suitable with deionized water or glycol-water blends.

– Compact structure saves room in densely stuffed power cabinets.

– Attire temperature circulation across the heatsink surface area avoids hotspots.

– Corrosion-resistant covering prolongs service life even in severe environments.

** Compliance: ** Satisfies IEC and RoHS requirements for security and environmental sustainability. The SS14 collection is examined for leak-proof performance under long term operational tension, making it a durable remedy for commercial power control systems calling for dependable thermal monitoring.

(thyristor water-cooling heatsinks SS14)

Applications of thyristor water-cooling heatsinks SS14

The SS14 thyristor water-cooling heatsink is a vital option for high-power digital systems calling for efficient thermal administration. Thyristors, semiconductor tools utilized for power control and switching, create considerable warm during procedure, which can weaken performance and decrease life expectancy without correct cooling. The SS14 utilizes advanced water-cooling innovation to dissipate warm properly, guaranteeing dependability sought after environments.

In industrial motor drives and automation systems, the SS14 preserves thyristor temperatures throughout heavy loads and frequent cycling, protecting against thermal runaway and lessening downtime. Renewable energy applications, such as solar inverters and wind generator converters, rely on the SS14 to stabilize power conversion processes. Efficient warmth dissipation optimizes power output and safeguards components from thermal stress, important in variable-load settings.

Electric vehicle (EV) powertrains and billing infrastructure benefit from the SS14’s small style and durable air conditioning ability. Managing warm from high-current operations ensures risk-free, efficient efficiency in battery monitoring and electric motor control systems. In a similar way, welding equipment utilizes the SS14 to sustain constant thyristor function throughout high-current arcs, making sure steady procedure and decreasing maintenance.

High-voltage straight present (HVDC) transmission systems incorporate the SS14 to cool thyristors in converters and rectifiers, maintaining grid security by avoiding overheating-related failings. Constructed with corrosion-resistant products like light weight aluminum or copper, the heatsink functions enhanced water channels for efficient heat transfer, also in severe conditions. Its modular layout streamlines installation across diverse configurations, decreasing compatibility concerns.

The SS14’s ability to handle thermal loads enhances functional performance, reduces failing threats, and extends part longevity. Industries such as production, renewable resource, auto, and power distribution depend upon the SS14 for reliable thermal management, making it important in modern high-power electronics. By integrating sturdiness, versatility, and exceptional air conditioning performance, the SS14 makes certain thyristors run within risk-free temperature level thresholds, sustaining essential applications where accuracy and reliability are critical.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality thyristor water-cooling heatsinks SS14, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of thyristor water-cooling heatsinks SS14

The thyristor water-cooling heatsink SS14 is a specialized thermal management solution designed to dissipate heat generated by high-power thyristors in industrial applications. Below are the five most frequently asked questions about this product, answered concisely:

**1. What is the primary function of the SS14 water-cooling heatsink?**

The SS14 efficiently transfers heat away from thyristors using circulating coolant, preventing overheating and ensuring stable performance in high-power electronics like motor drives, power supplies, and rectifiers. Its water-cooling design offers superior heat dissipation compared to passive air cooling.

**2. Why choose water cooling over traditional air cooling for thyristors?**

Water cooling provides higher thermal conductivity, enabling faster heat removal from high-density thyristor setups. The SS14 handles extreme thermal loads, reduces hot spots, and maintains consistent device temperatures, which prolongs component lifespan and minimizes downtime in demanding environments.

**3. How does the SS14 heatsink’s design enhance cooling efficiency?**

The SS14 features optimized internal coolant channels and high-quality materials like corrosion-resistant aluminum or copper alloys. This ensures rapid heat absorption from thyristors and efficient transfer to an external radiator, even in continuous high-load operations.

**4. Is the SS14 difficult to install or maintain?**

Installation requires integrating the heatsink with the thyristor assembly and connecting it to a closed-loop coolant system. Maintenance involves periodic checks for leaks, coolant quality, and flow rates. The design prioritizes user-friendliness, with most systems needing only annual servicing unless operated in harsh conditions.

**5. Is the SS14 compatible with all thyristor models?**

The SS14 is adaptable to most standard thyristor sizes and configurations. However, compatibility depends on mounting dimensions, thermal requirements, and electrical isolation needs. Customizable brackets or interface materials are available to ensure seamless integration with specific thyristor setups.

In summary, the SS14 water-cooling heatsink offers reliable, high-efficiency thermal management for critical thyristor applications, combining durability, ease of use, and adaptability to diverse industrial systems.

(thyristor water-cooling heatsinks SS14)

REQUEST A QUOTE

RELATED PRODUCTS

High Power Cnc Extruded Enclosure heatsink Profile Radiator Cooler Igbt Extrusion Aluminum Car Amplifier Heat Sink

High quality stainless steel heatsink plate 201 210 304 316 316L 410 420 steel plates food grade stainless steel plate

Custom Design Square heatsink Anodized Extruded Large Aluminum Extrusion Profile Heat Sink

Mass Production High Quality 6061 6063 Heatsink Profile Large Aluminium Custom Radiator CNC Extruded Heat Sink

High Power Dense Fin Anodized Black heatsink Aluminum Skiving Passive Heat Sink For Semiconductor