Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Heatlinks

Heatlinks function by providing a path of low thermal resistance between a heat source (such as an electronic component) and a heat sink or cooling system. They can be particularly useful in environments where space constraints limit the use of traditional cooling methods, or when a passive thermal management solution is preferred.

Heatlinks can operate based on different principles, including phase change materials, solid-state conduction, or even fluid-based systems. The choice of technology depends on the application’s specific requirements, such as operating temperature range, power dissipation levels, and spatial limitations.

Features of Heatlinks

High Thermal Conductivity: Designed to offer high thermal conductivity, ensuring efficient heat transfer from the source to the sink.

Compact Design: Often compact, allowing them to fit into tight spaces within electronic assemblies or other equipment.

Passive Operation: Typically do not require external power to function, relying instead on the natural flow of heat from hot to cold areas.

Durability and Reliability: Manufactured to withstand repeated thermal cycles and harsh environmental conditions without degradation of performance.

Low Profile: Thin profiles help minimize the impact on the overall design of products.

Versatility: Can be tailored to fit various applications, from consumer electronics to industrial machinery and aerospace components.

Customizable: Available in different shapes, sizes, and configurations to meet specific design needs.

Cost-Effective: Provide an economical solution for thermal management compared to more complex cooling systems.

Minimal Maintenance: Generally require little to no maintenance once installed.

Environmental Compatibility: Designed to be compatible with a wide range of environments, including those that may contain corrosive elements or experience significant temperature fluctuations.

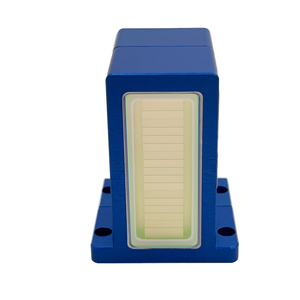

(Variety of Customized Heatsink For Leds Extruded Aluminum Heat Sink)

Specifications of Variety of Customized Heatsink For Leds Extruded Aluminum Heat Sink

Custom-made extruded light weight aluminum heat sinks for LEDs are crafted to enhance thermal administration, making certain extended lifespan and improved efficiency of LED systems. These warm sinks are crafted from high-grade light weight aluminum alloys, commonly 6063 or 6061, recognized for their outstanding thermal conductivity (180– 220 W/m · K) and light-weight resilience. Customization options satisfy varied LED applications, enabling changes in measurements, fin design, and architectural arrangement to satisfy certain cooling demands. Criterion lengths vary from 10 mm to 1000 mm, with widths and elevations flexible based on LED component dimension and heat dissipation demands. Fin density, elevation, and thickness can be tailored to stabilize surface area and airflow efficiency, ensuring ideal heat transfer.

Surface area therapies enhance functionality and aesthetics. Plating (black, silver, or custom-made colors) boosts corrosion resistance and thermal emissivity, while powder finish adds resilience for rough settings. Sleek or machine made finishes are available for precision applications. Thermal resistance (Rth) ranges 0.5 ° C/W and 2.0 ° C/W, relying on style complexity and LED power output.

Mechanical requirements consist of load-bearing ability as much as 50 kg for heavy-duty setups, with pre-tapped holes, placing braces, or clamps for protected installment. Personalized grooves or networks accommodate electrical wiring and vehicle drivers, enhancing combination. These warm sinks are compatible with high-power LEDs, COB varieties, SMD modules, and commercial lights systems, including streetlights and stadium components.

Ecological durability is prioritized, with IP-rated choices for outdoor or moist problems. Conformity with RoHS and REACH guarantees green materials. Suppliers offer prototyping, reduced MOQs, and rapid preparations (7– 2 week for bulk orders), supported by CFD simulations for performance recognition. Personalized designs straighten with customer-provided LED specifications, making certain smooth compatibility. Suitable for automotive, building, and gardening lights, these warmth sinks integrate accuracy design with cost-efficient scalability, providing reliable thermal services for high-efficiency LED applications.

(Variety of Customized Heatsink For Leds Extruded Aluminum Heat Sink)

Applications of Variety of Customized Heatsink For Leds Extruded Aluminum Heat Sink

Custom-made extruded aluminum heatsinks for LEDs are vital parts in taking care of thermal performance, making sure longevity, and preserving optimal effectiveness in varied LED applications. These heatsinks are made to dissipate warm generated by high-power LEDs, protecting against getting too hot and expanding the life-span of lighting systems. Their adaptability enables them to be tailored to details requirements, making them optimal for a wide variety of markets and make use of instances.

In ** automobile lights **, personalized LED heatsinks are critical for headlights, haze lights, and interior lights. They make sure stable efficiency under extreme temperature levels and resonances, while compact styles fit into limited areas without endangering cooling effectiveness. For ** consumer electronics **, such as LED TVs, clever light bulbs, and wearable tools, squeezed out aluminum heatsinks provide light-weight, slim profiles that integrate flawlessly right into smooth layouts while managing warm in energy-dense settings.

** Industrial and industrial lights ** relies upon robust heatsinks for high-bay LEDs, streetlights, and stockroom components. Custom shapes and fin densities maximize surface for warmth dissipation, also in messy or moist problems. In ** building illumination **, heatsinks are customized to blend with attractive components, making it possible for innovative styles for cove lighting, exterior illumination, and landscape tasks without compromising thermal administration.

The ** horticulture field ** makes use of specialized heatsinks in LED expand lights to preserve constant temperature levels, promoting plant development while lowering energy intake. Likewise, ** medical tools ** integrating LEDs, such as surgical lights or analysis tools, depends on precision-engineered heatsinks for reliability and quiet procedure in sensitive settings.

Customization choices consist of different lengths, widths, fin elevations, and surface treatments (e.g., plating for deterioration resistance or powder finishing for appearances). Extruded aluminum’s high thermal conductivity, durability, and cost-effectiveness make it a preferred product. By enhancing air movement and warmth circulation, these heatsinks improve LED efficiency, lower maintenance prices, and support energy-efficient remedies.

From wise cities utilizing LED streetlights to information centers using LED indications, tailored extruded aluminum heatsinks adjust to evolving technical needs. Their duty in sustainability is significant, as efficient thermal monitoring reduces power waste and supports the transition to environment-friendly LED lighting systems worldwide. Whether for niche applications or automation, these heatsinks deliver integrity, precision, and scalability across industries.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Variety of Customized Heatsink For Leds Extruded Aluminum Heat Sink, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Variety of Customized Heatsink For Leds Extruded Aluminum Heat Sink

What is the benefit of using extruded aluminum for LED heatsinks? Extruded aluminum is a top choice for LED heatsinks due to its excellent thermal conductivity, lightweight nature, and cost-effectiveness. The extrusion process allows for precise, complex shapes that maximize surface area for efficient heat dissipation. Aluminum also resists corrosion, ensuring long-term durability in various environments, and can be easily customized to fit specific LED lighting requirements.

How customizable are these heatsinks? Customization options include size, shape, fin density, thickness, and surface finish (e.g., anodized, powder-coated, or bare aluminum). Manufacturers can tailor designs to match thermal performance needs, spatial constraints, or aesthetic preferences. Custom drilling, threading, and branding are also available. Provide your LED specifications, and the heatsink can be engineered to optimize heat management for your application.

What factors determine the right heatsink size for my LEDs? The size depends on the LED’s wattage, operating environment, and desired thermal performance. Higher-wattage LEDs generate more heat and require larger or fin-dense heatsinks. Ambient temperature, airflow, and enclosure space also influence sizing. Thermal simulation tools or manufacturer consultations can help determine the ideal dimensions to prevent overheating and ensure LED longevity.

Are these heatsinks easy to install? Yes. Most extruded aluminum heatsinks are designed for simple installation, with pre-drilled holes or slots compatible with standard LED modules. Use thermal interface materials like paste or pads to enhance contact between the LED and heatsink. Mounting hardware is often included, and lightweight aluminum simplifies handling. Custom designs can integrate mounting features for seamless integration into your lighting system.

How long do extruded aluminum heatsinks last? When properly matched to the LED’s thermal requirements, these heatsinks can last as long as the LEDs themselves—often 50,000+ hours. Aluminum’s corrosion resistance, especially with anodized finishes, ensures reliability in humid or harsh conditions. Regular dusting or cleaning maintains optimal performance. No maintenance beyond basic upkeep is needed, making them a low-effort, high-efficiency cooling solution.

(Variety of Customized Heatsink For Leds Extruded Aluminum Heat Sink)

REQUEST A QUOTE

RELATED PRODUCTS

Custom 6063 Anodized Enclosure Aluminum Extrusion Heat Sink,Cnc Milling Aluminum Extrusion Heatsink

Custom Size Amplifier Heatsink CNC Aluminum Extruded Fin Power Amplifier Heatsink

High Heat Dissipation heatsink Customized brass/copper heat sink For Computer Industry

Customized Industrial Aluminum Profile Shaped Heatsink Cnc Precision Machining Aluminum High-power High-density Tooth Heat Sink

Chengdacai Aluminum enclosure heat sink led grow light heatsink anodized aluminum skiving led heat sink