Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Phase Control Thyristor

A phase control thyristor, often referred to as a triac or SCR (Silicon Controlled Rectifier) in certain applications, is a semiconductor device used for controlling the amount of power delivered to a load by adjusting the phase angle at which the AC waveform is allowed to conduct. This method of control is known as phase angle control or simply phase control. Phase control thyristors are widely used in various applications that require precise regulation of electrical power, such as lighting dimmers, motor speed controls, temperature controllers, and more.

Features of Phase Control Thyristor

Phase Angle Control: Allows adjustment of the conduction point within each half-cycle of the AC waveform, enabling precise control over the average power delivered to the load.

High Efficiency: Operates with minimal losses when conducting, providing efficient power control.

Bidirectional Conductivity (Triacs): For AC applications, triacs can conduct current in both directions, making them suitable for full-wave control of AC loads.

Unidirectional Conductivity (SCRs): SCRs conduct current in one direction only and are typically used for half-wave control of AC or DC loads.

Gate Triggering: Conduction begins when a small current is applied to the gate terminal, allowing for easy control of the turn-on point.

Latching Current: Once triggered, the thyristor continues to conduct until the current through it falls below a certain level called the holding current.

Temperature Sensitivity: Performance can be affected by temperature changes, requiring thermal management considerations in design.

Voltage and Current Ratings: Available in a wide range of voltage and current ratings to suit different application needs.

Noise Generation: Can generate electromagnetic interference (EMI), necessitating proper filtering and shielding in sensitive applications.

Protection Mechanisms: Often include built-in protection against overvoltage and overcurrent conditions to safeguard the device and connected systems.

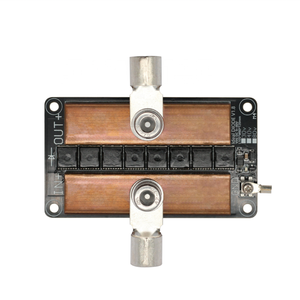

(Phase controller Three-phase thyristor module heating control unit ARHA8-5-4-125-P-3-0 Power regulator)

Specification of Phase controller Three-phase thyristor module heating control unit ARHA8-5-4-125-P-3-0 Power regulator

The ARHA8-5-4-125-P-3-0 Phase Controller is a three-phase thyristor module developed for heating control in industrial settings. It manages power circulation to maintain precise temperature levels in systems like heaters, stoves, and thermal processors. The system makes sure stable procedure by readjusting electrical input based upon real-time needs. This improves power performance and reduces waste.

The controller handles voltages up to 480V a/c and present rankings as much as 125A. It supports an optimal power ability of 75 kW. The tool approves 4-20 mA or 0-10 V DC input signals. Customers can choose in between phase-angle or burst-fire control settings. Phase-angle setting enables smooth power modification. Burst-fire mode switches over power in cycles for tons security. Both approaches ensure minimal harmonic interference.

Integrated safety features protect versus overloads, brief circuits, and getting too hot. These safeguards avoid tools damages and improve driver security. The module fulfills CE and UL certifications. It abides by worldwide criteria for industrial applications.

The design makes use of sturdy products to endure extreme environments. It operates dependably in temperature levels from -20 ° C to 60 ° C. High moisture or dust degrees do not affect performance. This rugged construction minimizes maintenance demands and downtime.

Installment is straightforward. The system integrates with existing control systems using basic user interfaces. Real-time surveillance is possible via software tools or neighborhood displays. Operators readjust setups from another location or on-site. This flexibility supports vibrant process adjustments.

The ARHA8-5-4-125-P-3-0 enhances heating processes by keeping constant temperatures. It protects against energy waste triggered by variations. Industrial individuals gain from reduced operational prices and extensive devices life. The module matches applications needing exact thermal management. Its reliability makes it a functional choice for requiring settings.

(Phase controller Three-phase thyristor module heating control unit ARHA8-5-4-125-P-3-0 Power regulator)

Applications of Phase controller Three-phase thyristor module heating control unit ARHA8-5-4-125-P-3-0 Power regulator

The ARHA8-5-4-125-P-3-0 phase controller three-phase thyristor component heating control system takes care of power in industrial heater. It changes voltage and present to heating elements utilizing thyristors. This guarantees specific temperature level control. The device operates in settings requiring secure heat output. It takes care of high-power tons up to 125A. Applications consist of industrial ovens, furnaces, and thermal handling equipment.

Industrial heater utilize the ARHA8-5-4-125-P-3-0 for steel treatment procedures. Annealing, setting, and toughening up need precise temperature policy. The device adjusts power in actual time. This stops getting too hot or underheating. It preserves regular item high quality.

Plastic manufacturing relies upon regulated heating for extrusion and molding. The unit makes certain even heat circulation. Product flow stays attire. Production issues decrease. Power waste declines.

Semiconductor production needs specific thermal management. The ARHA8-5-4-125-P-3-0 manages home heating during wafer handling. Temperature security protects against product damages. It sustains high-yield production.

Chemical processing uses the device for reactor heating. Reactions usually require specific temperature arrays. The module adjusts power efficiently. Process performance improves. Safety risks lower.

Food processing tools like commercial dryers use the device. Consistent warmth stops unequal drying. Item life span extends. Energy expenses stay manageable.

The system incorporates with existing automation systems. Sensors feed temperature data to the controller. Modifications happen automatically. Hand-operated treatment minimizes. Downtime decreases.

Heavy machinery elements like boilers utilize the module. Quick load adjustments are handled without power rises. Tools life-span increases. Maintenance expenses decrease.

The ARHA8-5-4-125-P-3-0 matches rough settings. Dust, dampness, and temperature variations do not impact efficiency. Dependability remains high. Manufacturing schedules stay on track.

Interface simplify procedure. Criteria are set by means of intuitive controls. Real-time surveillance tracks performance. Alerts notify drivers of issues. Repairing quicken.

The system sustains several phase arrangements. Compatibility with three-phase systems is basic. Setup requires very little wiring. Retrofitting old systems is simple.

Power efficiency is a vital advantage. Power use aligns with actual need. Excess consumption is prevented. Functional costs diminish. Ecological effect decreases.

Industrial facilities focus on security. The component includes overload defense. Circuit failures are protected against. Fire risks decrease. Worker safety and security enhances.

Scalability meets diverse requirements. Little workshops and huge plants make use of the system. Custom-made settings adapt to specific procedures. Adaptability sustains varied applications.

Toughness guarantees long-term usage. Components stand up to wear. Replacement cycles expand. Total possession expenses stay reduced.

Technical support is readily available around the world. Professionals assist with arrangement and optimization. System efficiency maximizes. User self-confidence expands.

Company Profile

Luoyang Datang Energy Tech Co.Ltd(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Phase controller Three-phase thyristor module heating control unit ARHA8-5-4-125-P-3-0 Power regulator, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Phase controller Three-phase thyristor module heating control unit ARHA8-5-4-125-P-3-0 Power regulator

The ARHA8-5-4-125-P-3-0 phase controller manages heating in three-phase systems using thyristor modules. It adjusts power to heating elements for precise temperature control. Here are common questions about the unit.

What does the ARHA8-5-4-125-P-3-0 do? It regulates electrical power to heating systems. It uses thyristors to control voltage and current. This maintains stable temperatures in industrial processes like furnaces or ovens.

How does the unit work? It monitors temperature signals from sensors. It adjusts thyristor firing angles to change power output. This method ensures smooth heating without sudden spikes. It protects equipment from damage.

What are the key features? The unit supports three-phase loads up to 125A. It includes overcurrent and overheating protection. It works with standard control signals like 4-20mA or 0-10V. The compact design saves space in control panels.

Where is it typically used? Common applications include plastic molding machines, industrial kilns, and food processing systems. It suits any setup needing accurate, adjustable heat control.

Is the unit safe for long-term use? Built-in safeguards prevent overloads and short circuits. The thyristor module reduces wear by minimizing power surges. Regular maintenance checks ensure reliability. Proper installation by trained personnel is required.

(Phase controller Three-phase thyristor module heating control unit ARHA8-5-4-125-P-3-0 Power regulator)

REQUEST A QUOTE

RELATED PRODUCTS

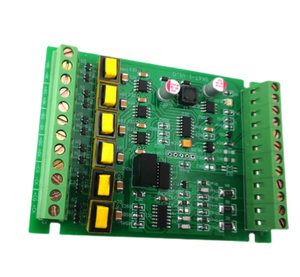

Industrial Controls Scr Phase Control Thyristor R800CH18FFO Gto Thyristor

Whole KP Series SCR Thyristor 300A 500A 1600V Phase Control Thyristor

5STP 17H5200 ABB Phase Control Thyristor PCT Silicon Wafer Material Hitachi Energy Product

Disc type SCR / phase control thyristor / fast thyristor

KK200A 600V SCR Phase Control Thyristor High-Voltage Inverter & Converter