Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Rectifier Diodes

Rectifier diodes are semiconductor devices used primarily for converting alternating current (AC) into direct current (DC). They allow current to flow easily in one direction while blocking it in the opposite direction. This unidirectional property makes them essential components in power supplies, signal processing, and various electronic circuits. Rectifier diodes can handle a wide range of currents and voltages, making them versatile for numerous applications.

Features of Rectifier Diodes

Unidirectional Conductivity: Facilitates current flow in one direction only, effectively blocking reverse current.

High Current Handling: Designed to carry substantial forward currents, suitable for high-power applications.

Peak Inverse Voltage (PIV): Can withstand high reverse voltages without breaking down.

Low Forward Voltage Drop: Minimizes energy loss as heat, improving efficiency.

Fast Recovery Time: Quickly transitions from conducting to non-conducting states, beneficial for high-frequency applications.

Thermal Stability: Maintains performance across a broad temperature range, ensuring reliability in varying conditions.

Compact Size: Small form factor facilitates integration into compact electronic designs.

Cost-Effective: Provides an economical solution for AC-to-DC conversion needs.

Variety of Packages: Available in multiple packaging options to fit different mounting requirements.

(DIODE RECTIFIER MODULE DF75BA80 DF50BA80)

Specification of DIODE RECTIFIER MODULE DF75BA80 DF50BA80

The DF75BA80 and DF50BA80 diode rectifier components are made for transforming alternating current (AIR CONDITIONER) to guide present (DC) in commercial applications. These components take care of high-power operations effectively. They match use in motor drives, power supplies, welding devices, and renewable energy systems. The DF75BA80 sustains an optimum recurring reverse voltage of 1600V. The DF50BA80 shares the exact same voltage rating. Both components supply reputable performance under heavy loads.

The DF75BA80 has an ordinary forward present score of 75A. The DF50BA80 deals with 50A. Peak surge existing capability reaches 1100A for the DF75BA80 and 800A for the DF50BA80. This makes sure security during abrupt power spikes. Low ahead voltage decrease reduces energy loss. Thermal resistance is maintained low to boost heat dissipation. The components operate within a junction temperature level series of -40 ° C to 150 ° C. This permits use in severe settings.

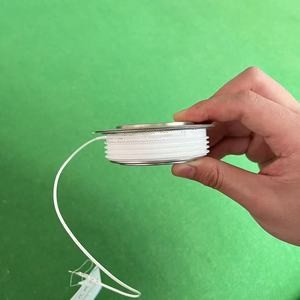

Each component makes use of a press-fit bundle design. It makes certain protected mechanical links. The compact structure conserves space in electrical assemblies. Installing is basic with typical hardware. The terminals are copper-based. They supply high conductivity and corrosion resistance. Isolation voltage between terminals and the base plate goes beyond 2500V. This prevents brief circuits.

The components meet global security criteria. They consist of qualifications like UL acknowledgment and RoHS compliance. Examining covers electric efficiency, thermal biking, and vibration resistance. Rugged building and construction ensures long-term resilience. Upkeep requirements are very little.

Applications include industrial electric motor controllers, battery chargers, and UPS systems. The modules integrate easily right into three-phase rectifier arrangements. They match well with warmth sinks for enhanced thermal monitoring. Custom configurations are available for specialized demands.

The DF75BA80 and DF50BA80 prioritize efficiency and integrity. They reduce downtime in vital operations. Their design focuses on user-friendly installation. Performance remains regular across varying load problems. These components are a functional choice for high-demand electric systems.

(DIODE RECTIFIER MODULE DF75BA80 DF50BA80)

Applications of DIODE RECTIFIER MODULE DF75BA80 DF50BA80

The DIODE RECTIFIER COMPONENT DF75BA80 and DF50BA80 are essential elements in power conversion systems. These modules transform rotating current (A/C) to route present (DC). They are commonly made use of in industrial and industrial applications. High efficiency and dependability make them appropriate for demanding settings. The DF75BA80 handles greater existing ratings compared to the DF50BA80. Both models are constructed with tough designs. They endure voltage changes and temperature variations.

Industrial machinery usually uses these rectifier components. Motor drives, welding equipment, and battery chargers count on stable DC power. The modules ensure consistent efficiency in these systems. They reduce power loss during conversion. This improves overall system performance. Their compact size allows easy combination into existing configurations. Upkeep needs are low. This decreases downtime in manufacturing settings.

Power supply devices in telecommunications and data centers utilize these diodes. Uninterrupted DC power is critical for web servers and communication tools. The DF75BA80 and DF50BA80 offer steady voltage result. They safeguard delicate electronic devices from power surges. Thermal management attributes avoid getting too hot. This prolongs the life-span of both the modules and connected devices.

Renewable energy systems gain from these rectifier modules. Solar inverters and wind turbines require efficient AC-to-DC conversion. The modules handle variable input voltages from renewable resources. They make sure secure power delivery to grids or storage space systems. Their durability suits outdoor installments. Harsh weather conditions do not jeopardize efficiency.

Automotive applications include electric automobile billing terminals. The components convert air conditioning grid power to DC for battery charging. Quick billing systems require high present capacity. The DF75BA80 satisfies these requirements. The DF50BA80 is utilized in lower-power charging units. Both versions sustain quick energy transfer. Security features protect against short circuits and overloads.

Durable equipment like cranes and lifts utilize these rectifiers. Smooth DC power guarantees precise control of mechanical operations. The components reduce electrical sound. This prevents interference with control signals. Their durable building withstands vibration and shock. Industrial automation systems depend upon this dependability.

The DF75BA80 and DF50BA80 are versatile remedies for modern-day power needs. They adapt to varied applications. Efficiency stays constant under varying tons. Advanced materials make certain long-lasting operation. These modules are crucial for effective power management throughout markets.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality DIODE RECTIFIER MODULE DF75BA80 DF50BA80, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of DIODE RECTIFIER MODULE DF75BA80 DF50BA80

The diode rectifier modules DF75BA80 and DF50BA80 convert alternating current (AC) to direct current (DC). They handle high-power applications. Common questions include their uses, specifications, installation steps, maintenance needs, and differences between models.

What is the purpose of these modules? They change AC to DC in industrial systems. This process powers machinery needing stable DC supply. Examples include motor drives, power supplies, welding equipment.

Where are these modules typically used? Factories, manufacturing plants, renewable energy systems use them. They work in environments requiring reliable high-current rectification. Harsh conditions like high temperatures or dust are manageable due to robust design.

What are the key features? High thermal conductivity materials prevent overheating. Low forward voltage drop improves efficiency. The modules support three-phase AC input. Built-in safety mechanisms protect against surges or short circuits.

How to install and maintain the modules? Mount them on heat sinks using thermal paste. Tighten screws evenly for proper contact. Connect terminals following wiring diagrams. Check connections periodically for looseness or corrosion. Clean dust from surfaces. Monitor temperature during operation. Replace modules showing signs of damage or performance drop.

What’s the difference between DF75BA80 and DF50BA80? The DF75BA80 handles 75A average current. The DF50BA80 manages 50A. Both share similar voltage ratings and design. Choose based on current requirements. Higher current models suit heavier loads. Lower current versions fit smaller systems.

These modules ensure stable DC output. They reduce energy loss during conversion. Users report longer service life with regular maintenance. Compatibility with standard industrial setups simplifies integration. Technical support is available for troubleshooting.

(DIODE RECTIFIER MODULE DF75BA80 DF50BA80)

REQUEST A QUOTE

RELATED PRODUCTS

MEO450-12DA(H) high voltage rectifier diodes In stock

Sixpack Three Phase Standard SA075G120W2 Diode Bridges high voltage igbt module driver transistors rectifier 650V 1200V

25A 1000V Diode Bridge Rectifier KBU2510

bridge rectifier for brake motor

FR101-FR107 Plastic Fast Recovery Rectifiers