Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Overview of Rectifier Diodes

Rectifier diodes are semiconductor devices used primarily for converting alternating current (AC) into direct current (DC). They allow current to flow easily in one direction while blocking it in the opposite direction. This unidirectional property makes them essential components in power supplies, signal processing, and various electronic circuits. Rectifier diodes can handle a wide range of currents and voltages, making them versatile for numerous applications.

Features of Rectifier Diodes

Unidirectional Conductivity: Facilitates current flow in one direction only, effectively blocking reverse current.

High Current Handling: Designed to carry substantial forward currents, suitable for high-power applications.

Peak Inverse Voltage (PIV): Can withstand high reverse voltages without breaking down.

Low Forward Voltage Drop: Minimizes energy loss as heat, improving efficiency.

Fast Recovery Time: Quickly transitions from conducting to non-conducting states, beneficial for high-frequency applications.

Thermal Stability: Maintains performance across a broad temperature range, ensuring reliability in varying conditions.

Compact Size: Small form factor facilitates integration into compact electronic designs.

Cost-Effective: Provides an economical solution for AC-to-DC conversion needs.

Variety of Packages: Available in multiple packaging options to fit different mounting requirements.

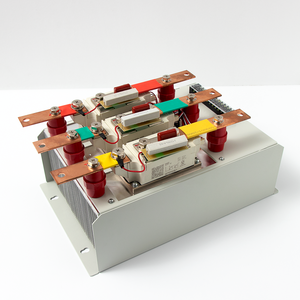

(Stud rectifier diode for welding machine Screw rectifier SKN SKR 100/16/14/12/18 130/04 240/16 Diode rectifier)

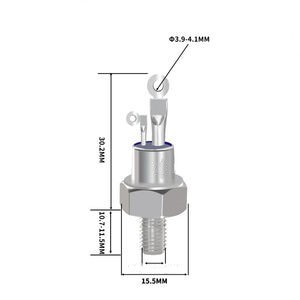

Specification of Stud rectifier diode for welding machine Screw rectifier SKN SKR 100/16/14/12/18 130/04 240/16 Diode rectifier

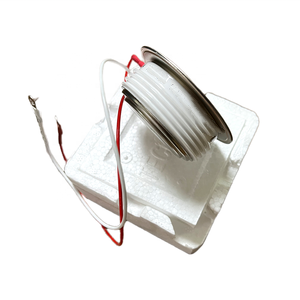

The stud rectifier diode is developed for welding equipments, making sure trustworthy efficiency in high-power applications. It converts alternating existing (AC) to direct existing (DC), crucial for secure welding procedures. The diode is developed with a rugged stud building and construction, offering strong mechanical assistance and reliable warm dissipation. This layout suits heavy-duty environments, managing high currents without overheating.

The SKN and SKR series include designs like 100/16/14/ 12/18, 130/04, and 240/16. These diodes sustain onward currents up to 100A-240A, depending on the model. Reverse voltage ratings vary from 16V to 240V, ensuring defense against voltage spikes. The stud base is made of premium copper, lowering resistance and improving conductivity. A silicon semiconductor layer boosts resilience and thermal stability.

Installing the diode is simple due to its threaded stud design. It fits securely right into welding machine settings up, reducing loose links. The robust housing resists vibration, wetness, and temperature level changes. This makes it appropriate for commercial setups where devices encounters extreme conditions.

The rectifier diode makes certain constant DC outcome, crucial for smooth welding arcs. It lessens power loss, boosting device efficiency. High rise present capacity allows it to take care of unexpected power spikes without damage. This feature prolongs the diode’s lifespan, minimizing replacement costs.

Compatibility covers different welding systems, consisting of MIG, TIG, and arc welders. The SKN and SKR series fulfill international standards for safety and security and performance. Regular upkeep is basic– tidy the stud get in touches with occasionally to stop corrosion. Proper installation ensures optimum heat transfer, staying clear of overheating problems.

These diodes are evaluated under extreme loads to guarantee integrity. They do well in constant operation, keeping steady outcome under hefty usage. The mix of copper and silicon materials makes certain low power loss and high thermal endurance.

Individuals gain from lowered downtime and regular welding high quality. The rectifier’s layout concentrates on customer safety, with protected housings to stop electric dangers. It incorporates effortlessly right into existing welding setups, needing no unique modifications.

Designers prioritize durability and effectiveness in these diodes. They are extensively used in automobile repair service, building and construction, and metal construction. The product’s durability makes it a favored option for professionals needing reliable performance.

The SKN and SKR rectifier diodes are offered in several setups. Selection relies on the welding machine’s voltage and existing requirements. Detailed specs aid customers match the proper diode to their tools.

(Stud rectifier diode for welding machine Screw rectifier SKN SKR 100/16/14/12/18 130/04 240/16 Diode rectifier)

Applications of Stud rectifier diode for welding machine Screw rectifier SKN SKR 100/16/14/12/18 130/04 240/16 Diode rectifier

Stud rectifier diodes are essential parts in welding devices. They transform alternating existing (AC) to route present (DC). This process ensures stable power result for welding tasks. Welding needs precise control of electrical arcs. Stud diodes deal with high currents and voltages. This makes them reliable for commercial welding devices.

The SKN and SKR collection (100/16/14/ 12/18, 130/04, 240/16) are developed for durable usage. These diodes take care of power rises without failing. Welding makers produce warmth during procedure. Stud rectifier diodes hold up against heats. Their robust design avoids getting too hot. This extends the lifespan of the welding device.

These diodes are utilized in both manual and automatic welding systems. They make certain constant current flow. Consistent existing protects against weak welds or product damage. SKN and SKR diodes adjust to various welding approaches. Instances consist of stick welding, TIG welding, and MIG welding. Their flexibility fits different commercial demands.

Resilience issues in extreme atmospheres. Stud rectifier diodes withstand resonance, dust, and moisture. Manufacturing facilities and building and construction websites usually have difficult problems. The diodes keep efficiency despite these challenges. This reliability minimizes downtime for repair services.

The SKN/SKR 100/16/14/ 12/18 designs handle tool to high power loads. The 130/04 variation is compact for smaller sized devices. The 240/16 diode supports high-voltage applications. Each model matches particular welding needs. Customers choose the best diode based upon device capacity.

Efficiency is crucial in welding procedures. Stud rectifier diodes decrease energy loss. Much less squandered power decreases electricity costs. They likewise lower heat buildup in the device. Cooler systems operate safely for longer periods.

Upkeep is simple for these diodes. They have a solid-state style with no relocating parts. Technicians check links and tidy surface areas regularly. This makes sure optimum performance over time.

Welding top quality depends on stable DC outcome. Stud rectifier diodes provide smooth present. This leads to strong, tidy welds. Flaws like spatter or incomplete blend are reduced. Industries like automotive manufacturing and steel construction depend on this uniformity.

Compatibility with existing systems is another advantage. SKN and SKR diodes fit typical welding maker layouts. Updating or replacing old diodes is simple. This saves time and prices for organizations.

Stud rectifier diodes balance efficiency and toughness. They meet the demands of modern welding applications. Their role in power conversion is irreplaceable. Welding devices furnished with these diodes run effectively. They provide specialist outcomes across sectors.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Stud rectifier diode for welding machine Screw rectifier SKN SKR 100/16/14/12/18 130/04 240/16 Diode rectifier, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Stud rectifier diode for welding machine Screw rectifier SKN SKR 100/16/14/12/18 130/04 240/16 Diode rectifier

What is a stud rectifier diode for welding machines? It converts alternating current (AC) to direct current (DC) in welding equipment. This ensures stable power output for consistent welding performance. The SKN SKR models handle high currents and voltages common in industrial welding tasks. They suit both manual and automated welding setups.

Why choose SKN SKR 100/16/14/12/18 or 130/04 diodes? These diodes are built for durability under heavy use. They resist heat and electrical stress better than standard diodes. Their threaded stud design allows secure mounting. This prevents loose connections during machine vibrations. Compatibility with various welding systems makes them versatile.

How do you install these rectifier diodes? Clean the mounting surface first. Remove dirt or oxidation for proper contact. Tighten the stud with the correct torque to avoid damage. Follow manufacturer guidelines for torque values. Ensure cooling systems work well around the diode. Overheating shortens diode life.

What are the technical specs of SKN SKR 240/16 diodes? They handle up to 240 amps average current. Peak surge capacity reaches higher levels briefly. Reverse voltage ratings go up to 1600 volts. These specs prevent breakdown during power spikes. Check machine requirements match diode ratings before use.

How to maintain stud rectifier diodes? Inspect them regularly for physical damage or discoloration. Clean dirt from the diode body and connections. Use a soft brush or compressed air. Replace diodes showing cracks or burn marks. Avoid running the welding machine beyond its rated capacity. This reduces stress on the diodes.

(Stud rectifier diode for welding machine Screw rectifier SKN SKR 100/16/14/12/18 130/04 240/16 Diode rectifier)

REQUEST A QUOTE

RELATED PRODUCTS

24v 3000amp reverse copper plating equipment power supply dc electroplating rectifier 48v plating anodizing rectifier

Rectifier diode ZQ35A stud diode ZQ10A ZQ15A ZQ25A ZQ50A

6A10 Axial Ordinary Rectifier Diode R-6 1000V/6A Rectifier Diodo

Good thermal performance Temperature shock resistance ESD sensitivity level 3A Rectifier Diode A2CZ232

ZONCN Three Phase Standard PA025G120W1 Diode Bridges high voltage igbt module driver transistors rectifier 650V 1200V