Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

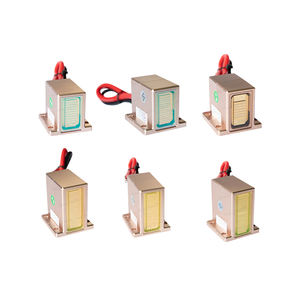

Overview of Single Three Phase Rectification Bridge Modules

Single three phase rectification bridge modules are essential components in power electronics, designed to convert alternating current (AC) from a three-phase supply into direct current (DC). These modules typically consist of six diodes arranged in a bridge configuration. They are widely used in industrial applications such as motor drives, welding equipment, and uninterruptible power supplies (UPS) systems due to their efficiency and reliability. The robust design ensures stable operation under varying load conditions, while the compact size facilitates easy integration into various electrical systems.

Features of Single Three Phase Rectification Bridge Modules

- High Efficiency: Optimized for minimal power loss during AC-to-DC conversion.

- Compact Design: Saves space within electrical installations, making it easier to integrate into existing systems.

- Robust Construction: Built to withstand harsh environments and provide long-term reliability.

- Wide Operating Temperature Range: Capable of operating efficiently across a broad temperature spectrum, enhancing versatility.

- Low Thermal Resistance: Facilitates effective heat dissipation, contributing to prolonged component life.

- Overcurrent Protection: Integrated safety features protect against potential damage from excessive currents.

- Simplified Wiring: Reduces installation complexity and time with straightforward connections.

- High Surge Current Capability: Handles transient overloads without compromising performance or longevity.

(Three Phases Diode Bridge Dfa75cb160 Dfa100cb160 Dfa150cb160)

Specification of Three Phases Diode Bridge Dfa75cb160 Dfa100cb160 Dfa150cb160

The 3 Phases Diode Bridge models DFA75CB160, DFA100CB160, DFA150CB160 are constructed for converting air conditioner to DC in commercial systems. These components take care of high-power procedures successfully. Each model serves different present needs. The DFA75CB160 sustains 75A ordinary onward existing. The DFA100CB160 handles 100A. The DFA150CB160 deals with 150A. All 3 share an optimal repeated reverse voltage of 1600V. This makes certain reliability in high-voltage environments. The diode bridges utilize a pressed-fit ceramic package style. This improves heat transfer. Thermal efficiency continues to be secure. The operating temperature variety is -40 ° C to +150 ° C. They operate in tough conditions. The modules abide by IEC, UL, and RoHS requirements. Safety and longevity are verified. Setup uses screw terminals. Links remain safe and secure. The DFA75CB160 has a compact size. It fits space-restricted arrangements. The DFA150CB160 is larger. It fits greater tons. All designs feature reduced forward voltage decline. Energy loss is decreased. Usual applications consist of motor drives, commercial power products, solar inverters. Surge current ability is robust. Short-term overloads posture no concern. Outside air conditioning is unnecessary under typical usage. Upkeep demands are very little. These devices are designed for long-term solution. They fit heavy-duty applications like welding tools, HVAC systems. Construction concentrates on durability. Downtime is limited. The diode bridges utilize isolation-free styles. Electrical safety and security is prioritized. Reverse recuperation time is optimized. Changing losses remain reduced. Material quality makes sure resistance to resonance and shock. Mounting options consist of conventional brace repairing. Positioning is uncomplicated. Custom-made setups are readily available. Compatibility covers most three-phase rectifier circuits. Performance remains consistent across voltage variations. Price efficiency is attained through extended lifespan. Replacement cycles are reduced. These bridges equilibrium power managing with compact design. They fulfill global industrial requirements.

(Three Phases Diode Bridge Dfa75cb160 Dfa100cb160 Dfa150cb160)

Applications of Three Phases Diode Bridge Dfa75cb160 Dfa100cb160 Dfa150cb160

The DFA75CB160, DFA100CB160, and DFA150CB160 three-phase diode bridges offer crucial duties in industrial and commercial power systems. These elements convert rotating current (AC) to route present (DC) efficiently. They take care of high-power applications, guaranteeing stable performance in demanding environments. Usual uses consist of commercial motor drives, power products, and renewable energy systems like wind turbines and solar inverters. Their style sustains heavy lots, making them ideal for machinery calling for regular DC power.

The DFA75CB160 version suits medium-duty applications. It supports currents approximately 75A and voltages up to 1600V. This makes it a suitable for cooling and heating systems, conveyor belts, and small production equipment. The DFA100CB160 deals with higher currents, approximately 100A. It works well in electrical car charging stations, commercial welding devices, and bigger motor controllers. The DFA150CB160, ranked for 150A, serves heavy machinery. Examples consist of mining devices, steel mills, and high-capacity generators. All 3 versions include robust thermal administration. This makes sure dependability under continuous procedure.

These diode bridges use sophisticated materials to reduce energy loss. Reduced forward voltage decrease lowers warm generation. This improves efficiency and extends part life-span. Their portable layout permits very easy combination into existing systems. Maintenance requirements are marginal, reducing lasting expenses.

Industrial automation counts on these diode bridges for precision control. They stabilize voltage changes in CNC machines, robotic arms, and assembly lines. In renewable resource arrangements, they guarantee smooth power conversion from photovoltaic panels or wind turbines to grid-compatible DC. This avoids disruptions triggered by variable energy inputs.

Safety functions include high isolation voltage and rise protection. These protect against brief circuits and tools damages. Compliance with international requirements like UL and IEC assurances reliability. Engineers rely on these parts for essential facilities jobs.

The diode bridges collaborate with numerous cooling techniques. Options consist of warmth sinks, followers, or liquid cooling. This flexibility adapts to different functional settings. Severe problems like high moisture or dust do not compromise efficiency.

Compatibility with contemporary control systems streamlines upgrades. Assimilation with PLCs, sensors, and IoT-enabled tools is seamless. This sustains clever production patterns. Replacement components are commonly available, minimizing downtime risks.

These designs satisfy industries focusing on efficiency and resilience. Their use extends production, energy, transport, and construction. Engineers choose them for jobs requiring reliable power conversion. Performance continues to be constant throughout temperature arrays. This makes them suitable for global applications.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality Three Phases Diode Bridge Dfa75cb160 Dfa100cb160 Dfa150cb160, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of Three Phases Diode Bridge Dfa75cb160 Dfa100cb160 Dfa150cb160

What are the DFA75CB160, DFA100CB160, and DFA150CB160 diode bridges used for?

These diode bridges convert alternating current (AC) to direct current (DC). They are commonly used in power supplies, motor drives, and industrial equipment. The devices handle high-voltage and high-current applications, ensuring stable performance in demanding environments.

What are the key features of these diode bridges?

The diode bridges offer high surge current capacity, low forward voltage drop, and efficient heat dissipation. They are built with insulated housings for safety. The models are designed for easy mounting on heat sinks. They operate reliably across a wide temperature range.

How do the three models differ?

The numbers in the model names indicate their current ratings. The DFA75CB160 handles 75A, the DFA100CB160 handles 100A, and the DFA150CB160 handles 150A. All three support a maximum voltage of 1600V. The higher-current models are suited for heavier loads.

What should users consider during installation?

Proper heat sink installation is critical. Ensure the mounting surface is clean and flat. Tighten screws evenly to avoid damaging the housing. Verify correct polarity when connecting terminals. Check all electrical connections are secure before powering the system.

Are these diode bridges reliable for long-term use?

Yes. The devices are built with rugged materials to withstand thermal stress and electrical surges. They undergo rigorous testing for quality assurance. Regular maintenance, like checking for loose connections or overheating, helps extend their lifespan. Follow the manufacturer’s guidelines for optimal performance.

(Three Phases Diode Bridge Dfa75cb160 Dfa100cb160 Dfa150cb160)

REQUEST A QUOTE

RELATED PRODUCTS

New Skbpc5016 Three-Phase Rectification Bridge Module 50a/1600v Bridge Stack 5 Pins

New And Original Three Phase Rectifier Bridge Module Mmd70e160x

Three-Phase Diode Rectifier Bridge Module Pt100s8 Pt100s12 Pt10112 Pt151s8

New And Original Three Phase Rectifier Bridge Module Vuo121-16no1

Three-Phase Single-Phase Diesel Generator Parts 10a, 20a, 40a, 60a, 100a Rectifier Bridge Module