Thyristors Online | High-Quality Power Semiconductors

PRODUCT PARAMETERS

Description

Introduction to Thyristor Diode Modules

Thyristor diode modules, often simply referred to as thyristors, are a type of semiconductor device used primarily for controlling and switching electrical power in various applications. They act as controlled switches, allowing current to flow when triggered by a small gate signal. Once turned on, they remain conducting until the current through them falls below a certain threshold or the direction of the current is reversed.

A thyristor module typically consists of multiple thyristors packaged together to handle higher currents or voltages than a single component could manage. These modules can be found in a variety of configurations, including SCR (Silicon Controlled Rectifier), TRIAC, and GTO (Gate Turn-Off) thyristors, each designed for specific types of power control tasks.

Features and Advantages of Thyristor Diode Modules

-

High Power Handling Capacity:

Thyristor modules are capable of handling high levels of power, making them suitable for industrial applications that require robust and reliable power management solutions. -

Efficient Power Control:

Thyristors offer precise control over the power delivered to a load. By controlling the timing of the gate pulse, it’s possible to adjust the amount of power being transferred, which is particularly useful in AC power control applications such as dimming lights or speed control of motors. -

Low Conduction Losses:

When fully on, thyristors have low forward voltage drops, resulting in minimal power losses during conduction. This efficiency contributes to lower operating temperatures and improved energy efficiency. -

Rugged Construction:

Designed for harsh environments, thyristor modules feature durable packaging that can withstand mechanical stress, temperature fluctuations, and other environmental factors typical in industrial settings. -

Compact Design:

Despite their ability to handle significant power, modern thyristor modules are compact, enabling space-saving designs in equipment where size and weight are critical considerations. -

Cost-Effective Solution:

Thyristor modules provide an economical way to implement powerful switching and control functions compared to alternative technologies that might not be as efficient or may cost more per unit of power handled. -

Simple Triggering Mechanism:

Thyristors require only a small gate current to turn on, which simplifies the design of control circuits. The triggering mechanism can be easily integrated into existing systems with minimal additional components. -

Wide Range of Applications:

From motor control and power supplies to welding machines and traction systems, thyristor modules find application across a broad spectrum of industries due to their versatile characteristics. -

Overcurrent Protection:

Many thyristor modules come equipped with built-in protection features against overcurrent conditions, safeguarding both the device itself and connected loads from potential damage. -

Fast Switching Speeds:

Advanced thyristor modules can switch states rapidly, which is beneficial in applications requiring quick response times or frequent switching cycles without compromising performance.

(New and original Rectifier diode module MDC110-12)

Specification of New and original Rectifier diode module MDC110-12

The MDC110-12 rectifier diode module is a new and original component built for high-power electrical applications. It handles up to 1200 volts and 110 amps, making it suitable for industrial equipment, power supplies, and motor drives. The module uses advanced semiconductor technology to ensure stable performance under heavy loads. Its low forward voltage drop reduces energy loss, improving overall system efficiency.

The design includes a compact, rugged housing made from heat-resistant materials. This protects internal components from overheating and physical damage. The module operates reliably in temperatures ranging from -40°C to 150°C. It works in harsh environments without losing functionality. A direct copper-bonded substrate enhances thermal conductivity, keeping temperatures even across the device.

Installation is straightforward. The module features screw terminals for secure connections. These terminals resist corrosion and vibration, ensuring long-term reliability. Polarity markings are clearly printed to prevent wiring errors. Maintenance requirements are minimal due to the durable construction.

Safety is a priority. The MDC110-12 meets international standards for electrical insulation and surge protection. It can withstand voltage spikes up to 1800 volts for short durations. Reverse recovery time is fast, reducing switching losses and electromagnetic interference. This makes the module compatible with sensitive electronic systems.

Applications include welding machines, battery chargers, and renewable energy systems. It performs well in both continuous and intermittent operations. The diode’s high surge capacity handles sudden current increases without failure. Consistent performance is guaranteed even under repetitive stress.

Materials are environmentally friendly. The module complies with RoHS and REACH regulations, avoiding hazardous substances. Its lead-free construction aligns with global sustainability goals. Packaging is anti-static and moisture-proof to prevent damage during storage or shipping.

Testing is rigorous. Each unit undergoes quality checks for voltage tolerance, current handling, and thermal stability. Batch testing ensures uniformity in performance. Reliability certifications from independent labs confirm the module meets industry standards.

The MDC110-12 replaces older models with higher failure rates. It offers better efficiency and durability at a competitive price. Technical support is available for integration challenges or custom requirements. Replacement parts are accessible through authorized distributors worldwide.

(New and original Rectifier diode module MDC110-12)

Applications of New and original Rectifier diode module MDC110-12

The MDC110-12 rectifier diode module is a new component designed for converting alternating current (AC) to direct current (DC) in electronic circuits. It works efficiently in high-voltage environments. This module suits industrial and commercial applications. Its compact size allows easy integration into existing systems. The design focuses on durability. It handles high power loads without overheating. This makes it reliable for continuous operation.

One key use is in power supply units. The MDC110-12 stabilizes voltage in devices like servers and telecom equipment. It ensures consistent energy flow. This prevents damage from voltage spikes. Factories use it in motor drives and automation systems. The module’s fast response time improves machinery performance. It reduces downtime caused by electrical issues.

Renewable energy systems benefit from this diode module. Solar inverters and wind turbines rely on stable DC conversion. The MDC110-12 handles variable input from natural sources. It maximizes energy harvest. Its low power loss cuts operational costs. Maintenance needs are minimal. This makes it ideal for remote installations.

Electric vehicle charging stations use the MDC110-12. It manages high currents safely. Chargers operate faster. Overheating risks drop. Drivers experience shorter wait times. The module’s rugged build withstands harsh outdoor conditions. Rain or dust do not affect performance.

Consumer electronics gain from this technology. Power adapters and LED drivers work more efficiently. Devices run cooler. Battery life extends. Home appliances like microwaves and air conditioners see fewer electrical failures. Users save on repair costs.

The MDC110-12 meets international safety standards. Certifications include CE and RoHS. Manufacturers trust its compliance. Global supply chains adopt it without delays. Customization options exist. Engineers tweak specs for specialized projects.

This rectifier diode module supports smart grid systems. It aids in balancing energy distribution. Grids become more resilient. Blackouts reduce. Cities relying on smart infrastructure find it useful. Data centers use it to protect sensitive servers.

Installation is straightforward. Technical support teams provide clear guides. No advanced training is needed. Companies upgrade systems without hiring experts. The module’s price fits small and large budgets. Bulk orders receive discounts.

Replacement parts are widely available. Suppliers stock the MDC110-12 globally. Shipping times stay short. Production lines avoid disruptions. Companies maintain steady output. Long-term warranties cover defects. Customers report high satisfaction rates.

The MDC110-12 adapts to future tech trends. Upgrades keep it compatible with new devices. Research teams test it for emerging applications. Early results show promise. Its design leaves room for modifications. Engineers experiment without starting from scratch.

This module works in extreme temperatures. Arctic winters or desert heat do not impair it. Military equipment uses it for field operations. Reliability under stress matters. The MDC110-12 delivers steady power in critical situations.

Safety features include overload protection. Circuits shut down automatically during faults. Fires or short circuits are less likely. Insurance costs drop for businesses. Employees face fewer workplace hazards. Legal liabilities decrease.

Performance data is transparent. Manufacturers publish test results openly. Buyers verify claims before purchasing. Third-party labs confirm efficiency ratings. Trust builds between suppliers and clients. Repeat orders increase.

The MDC110-12 reduces electronic waste. Its long lifespan means fewer replacements. Recycling programs accept worn-out units. Factories meet environmental goals. Governments incentivize green upgrades. Tax breaks apply.

Compatibility tests cover most major brands. Integration with legacy systems is smooth. Upgrading old machinery becomes affordable. Retrofitting costs stay low. Small workshops compete with larger firms. Market diversity grows.

Technical journals feature the MDC110-12. Industry experts recommend it. Conferences highlight its advantages. Engineers share success stories online. Social media buzz attracts new users. Sales rise steadily.

Production uses eco-friendly materials. Toxic chemicals are avoided. Workers handle components safely. Factories pass health inspections. Community complaints drop. Corporate reputations improve.

Error rates are minimal. Quality control checks every batch. Defective units get recycled. Customers receive flawless products. Negative reviews are rare. Brand loyalty strengthens.

The MDC110-12 suits startups and established firms. Scalability meets varying demands. Orders adjust as businesses grow. Inventories stay flexible. Economic shifts cause fewer disruptions.

Innovation continues. Feedback from users shapes updates. New versions address minor flaws. The module evolves with market needs. Competitors struggle to match its value.

Independent reviews praise its cost-effectiveness. Long-term savings outweigh initial prices. Budget managers approve purchases quickly. Projects stay on track. Delays from equipment failure shrink.

Training materials are free online. Video tutorials guide installers. Language options include Spanish and Mandarin. Global accessibility improves. Non-technical staff learn basics fast.

The MDC110-12 handles sudden power surges. Backup systems activate seamlessly. Data loss prevents. Hospitals and banks rely on it. Critical operations remain uninterrupted. Lives and assets stay protected.

Company Profile

PDDN Photoelectron Technology Co., Ltd.(sales@pddn.com) is one of the leading enterprises in power electronics technology and power products, which is fully involved in developing solar inverters, transformers, voltage regulators, distribution cabinets, thyristors, modules, diodes, heaters, and other electronic devices or semiconductors. We will be committed to providing users with high-quality, efficient products and considerate service.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you want high-quality New and original Rectifier diode module MDC110-12, please send us inquiries; we will be here to help you.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

By sea, by air, by express, as customers request.

Storage Conditions

1) Store in a dry environment at room temperature.

2) Avoid damp and high temperature.

3) Use immediately after opening the inner packing bag.

5 FAQs of New and original Rectifier diode module MDC110-12

What is the MDC110-12 Rectifier Diode Module? The MDC110-12 is a device designed to convert alternating current (AC) to direct current (DC). It serves as a critical component in power supply systems. The module ensures stable energy conversion. It suits applications requiring high efficiency. Its design focuses on durability. It operates reliably under varying loads.

What are the key features of the MDC110-12? The module supports a maximum voltage of 1200V. It handles currents up to 110A. The structure uses advanced thermal management. This prevents overheating during prolonged use. Its compact size saves space in setups. The materials resist corrosion. The module meets industry safety standards.

Where is the MDC110-12 commonly used? This diode module works in industrial power supplies. It integrates into motor drives. It supports renewable energy systems like solar inverters. Factories use it for machinery requiring steady DC power. Automotive charging systems employ it. It fits telecom infrastructure needing stable voltage.

How to install the MDC110-12 correctly? Mount the module on a flat surface. Use screws to secure it firmly. Apply thermal paste between the module and heat sink. Connect terminals using insulated cables. Check polarity matches the circuit requirements. Ensure proper ventilation around the unit. Test connections before powering the system.

What safety steps should users follow? Avoid exposing the module to moisture. Keep it away from flammable materials. Do not exceed voltage or current limits. Inspect for physical damage before installation. Turn off power during maintenance. Use protective gear when handling. Store in a dry environment. Replace the module if performance drops.

(New and original Rectifier diode module MDC110-12)

REQUEST A QUOTE

RELATED PRODUCTS

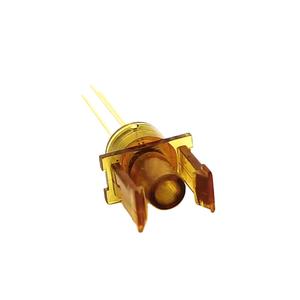

Diode laser stack LT HPL UPP KR STE CLE BML HYN American Coherent Bars laser transmitter emitter laser module 808 1064 755 810nm

Thyristor Module Power Switch Module IRKT91/16 1600V 95A Rectifier Diodes SCR

High power Optical 808nm 5W 2W single mode Fiber Coupled Laser Diode Module

Red 650nm 1mw 5mW F6 5V Laser Diode Module With PCB and wire

STOCK IGBT MODULE DIODE Rectifier Bridge Electronic components IC chips HA17458FP 458FP SOP8